World Chemical News, May 2020, by chemwinfo

28 May 2020

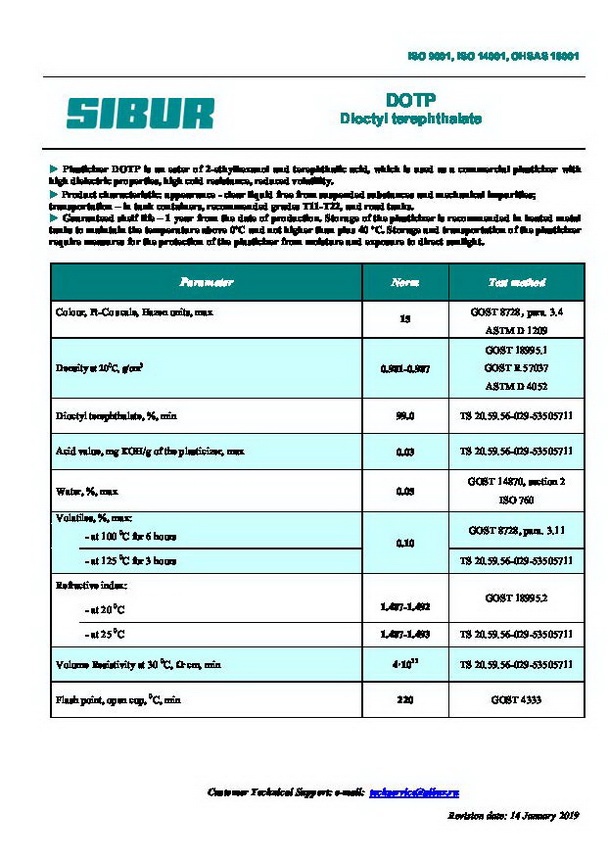

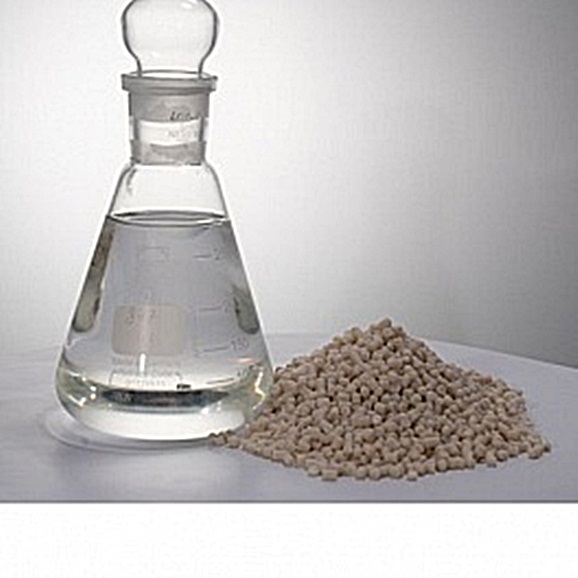

European Pharmacopoeia certication

The corresponding certicate allowed SIBUR

For instance, a Serbian company

that is also a customer of SIBUR started producing

medical compounds for surgical masks

treating coronavirus patients.

The mask body is made from a medical compound

based on SIBUR's PVC and DOTP.

28 May 2020

Gazprom reports that progress of Amur GPP

construction project reaches 61.9 per cent

It was noted at the meeting that

the progress of the project is currently

At the first and second production trains of the GPP,

which are going to come onstream in 2021,

installation of the core equipment is completed,

process pipelines are being installed

and provided with thermal insulation,

and start-up and commissioning activities

The construction site of the Amur GPP

is located near the town of Svobodny

The plant will have a design capacity

of 42 billion cubic meters of gas per year.

the world's largest helium production facilities

up to 60 million cubic meters.

The plant will have six production lines,

with the first two lines slated

The remaining lines will be consecutively

put in operation before the end of 2024.

In addition to natural gas and helium,

the GPP will produce ethane, propane, butane,

Gazprom Pererabotka Blagoveshchensk

is the project company for the Amur GPP project.

Construction management is carried out by

NIPIGAZ (part of the SIBUR Group),

42 billion cubic meters of natural gas per year.

Helium production: up to 60 million cubic meters per year.

Ethane production: around 2.5 million tons per year.

Propane production: around 1 million tons per year.

Butane production: around 500,000 tons per year.

Pentane-hexane fraction production: around 200,000 tons per year.

28 May 2020

bp licenses its latest generation PTA technology

to Dongying Weilian Chemical in China

Weilian Chemical is a subsidiary of

Dongying United Petrochemical Co., Ltd,

one of the leading manufacturers and distributors

of petroleum and petrochemical products in China.

Weilian Chemical intends to build

a 2.5 million tonnes per annum PTA production unit

at the Dongying Port Economic Development Zone

in eastern Shandong province, adding to

Dongying United Petrochemical’s existing

refineries and paraxylene (PX) facilities portfolio.

Weilian Chemical selected bp’s proprietary

PTA production technology for its new PTA unit

after a competitive, global bidding process

The design phase for the unit is underway

and is expected to be completed

during the first half of 2020.

First production is anticipated

by the second quarter of 2022.

BP Petrochemical technology (PCT)

World-leading technology enables each of our product lines

Purified Terephthalic Acid (PTA) and

low carbon PTA solution to manufacturers,

brand owners and their customers.

PTAIR® supports a carbon footprint of around 30%

lower than the average European PTA production.

28 May 2020

BASF and Red Avenue New Materials Group

have signed a joint agreement that grants

Red Avenue New Materials Group

the license to produce and sell

certified compostable aliphaticaromatic co-polyester

(PBAT) according to high BASF quality standards.

For that purpose, Red Avenue New Materials Group

will build a 60,000 metric tons PBAT plant

in Shanghai, using BASF`s process technology

in exchange for the access to raw material

from this plant which BASF will sell as ecoflex®.

Production at the new plant will start in 2022

and supply the market of biopolymers.

certified compostable and bio-based plastics

is expected to grow by around 15 percent per year.

With upcoming new laws and regulations

in a lot of countries enforcing

the use of compostable materials in

packaging, agricultural mulch films and bag applications,

the positive market development is expected to continue.

The BASF biopolymer ecoflex® was introduced

into the market in 1998 and is certified compostable

in accordance with DIN EN 13432 and ASTM D6400..

26 May 2020

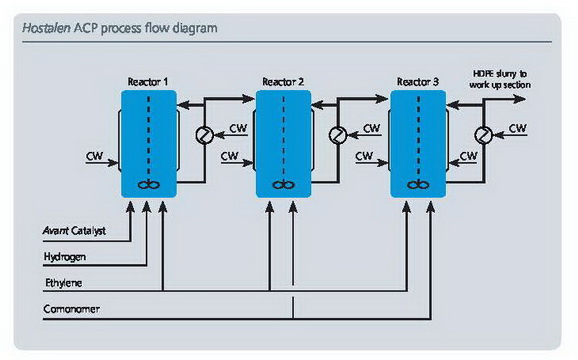

Sinopec Hainan Rening & Chemical Co., LTD. (Sinopec)

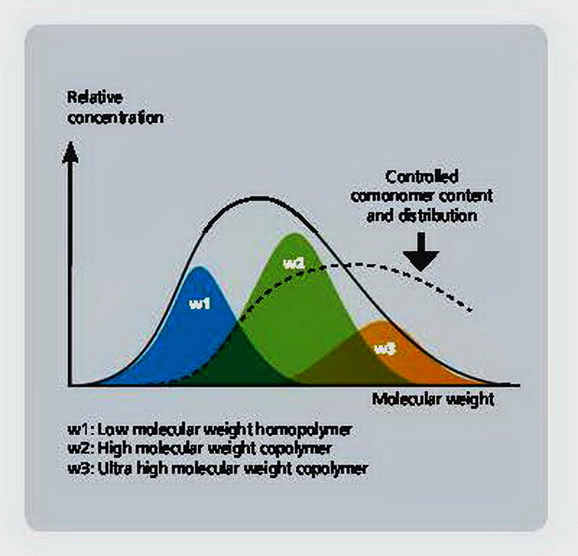

will use the LyondellBasell Hostalen

The process technology will be used for

a 300 KTA high density polyethylene (HDPE) facility

to be built in Yangpu, Hainan Province, P.R. China.

The Hostalen ACP low-pressure slurry process technology

high performance, multi-modal HDPE resins

with an increased stiffness/toughness balance,

impact resistance and high stress-cracking resistance

used in pressure pipe, lm and blow-molding applications..

>>DOWNLOAD LYONDELLBASELL hdpe ACP BROCHURE

26 May 2020

Clariant to increase mild surfactants capacity

Clariant’s global production network of

isethionates mild surfactants –

• Supports personal care brands and formulators

as consumers look for new mildness and hygiene claims

in applications such as syndet beauty bars,

body washes and cream shampoos

• Additional capacity available early 2021

As a global expansion, the investment targets

capacity increase and general modernization

Tarragona (Spain) manufacturing sites.

The general asset modernization will optimize

energy consumption and also aggregate options

for new SI grades (different Carbon-chains)..

GLOBAL TRADE MEDIA RELATIONS

STEFANIE NEHLSEN

Phone +41 61 469 63 63

stefanie.nehlsen@clariant.com

26 May 2020

Celanese Corporation (NYSE: CE) today announces

the European Commission’s Directorate-General

For Trade seeking Anti-Dumping duties

Ultra-High Molecular Weight Polyethylene (UHMWPE)

from Korea Petrochemical Industry Co., Ltd.

22 May 2020

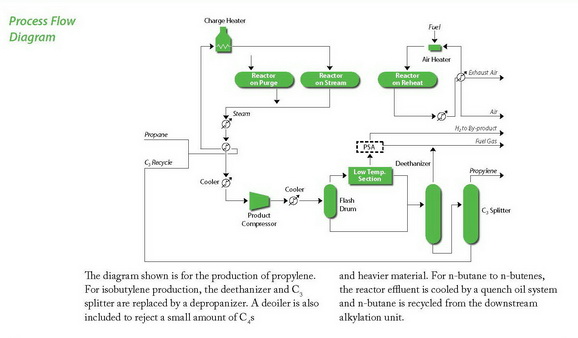

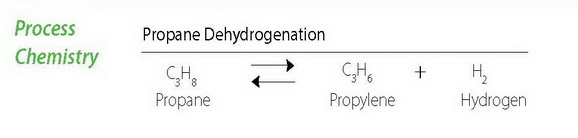

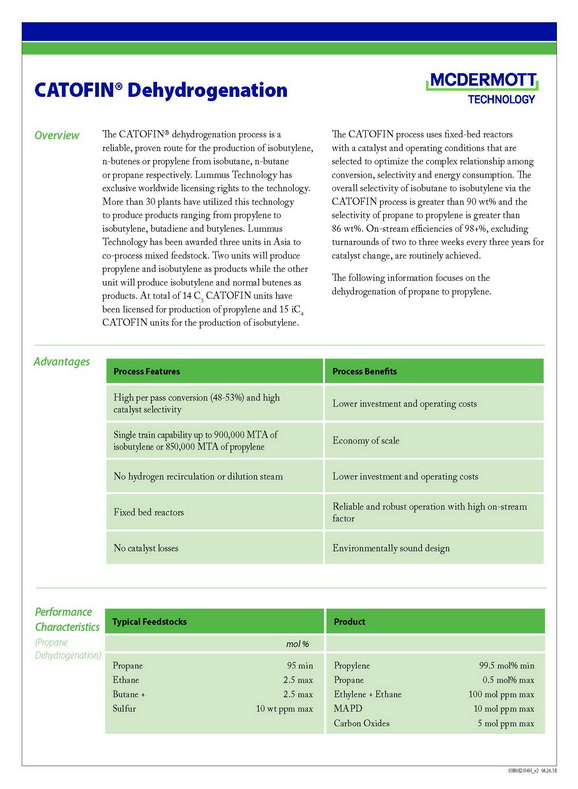

Clariant’s CATOFIN™ catalysts selected by

Advanced Petrochemical Company (APC)

for another PDH plant in the Middle East

• Advanced Global Investment Co., subsidiary of APC,

at new propane dehydrogenation (PDH) plant

• Clariant’s CATOFIN catalysts and

McDermott’s Lummus Process technology

chosen due to excellent performance

at APC’s existing propylene plant

• CATOFIN Technology is proven to greatly

enhance productivity and overall profitability

17 May 2020

CNOOC, SHELL and HUIZHOU GOVERNMENT

sign agreement to further expand

petrochemical complex in China

The expansion is planned to serve

intermediate and performance chemicals customers

in the key market of China, supplying products

including SMPO, polyols, ethylene glycol,

polyethylene and polypropylene.

a wide range of end products, in healthcare,

construction, fabrics, packaging,

For the first time in Asia, Shell would apply

its advanced technology for linear alpha olefins.

The project is intended to include construction

of a new 1.5 million-tonnes-per-year

ethylene cracker, with the mega-site

and enhanced competitiveness..

15 May 2020

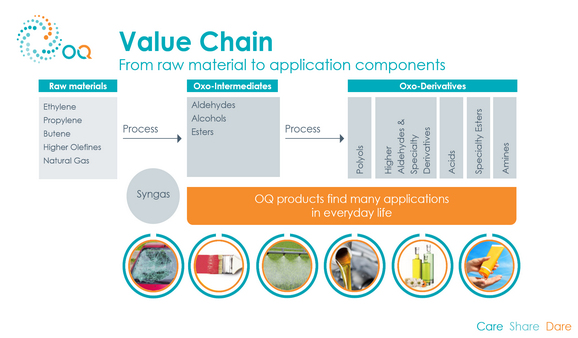

>>DOWLOAD OQ COMPANY PRESENTATION

Oxea has officially changed its corporate name to

as a token of its final integration into

the newly formed energy company OQ.

Complementing the name change is

reflecting the potential of the group, and

OQ aims to become a global leading energy company

and offers a diversified product mix,

including energy, polymers, and oxo chemicals..

12 May 2020

Sinopec Puts Its 16 Meltblown Non-Woven Fabric Lines

Sinopec Yizheng Chemical Fibre Co Ltd,

a subsidiary of Sinopec in Jiangsu Province,

put its 12th meltblown non-woven fabric production lines

Sinopec has now completed the construction

of all its 16 meltblown non-woven fabric production lines

After the full operation of the 16 production lines

and together with Sinopec's joint venture enterprises

seven tonnes of meltblown non-woven fabric every day,

the daily production capacity of the company

is expected to reach 37 tonnes, and

its annual production capacity will exceed 13,500 tons,

enough to make 13.5 billion medical face masks.

The meltblown non-woven fabric is

the filtering layer in the middle part of the mask

to absorb dust, bacteria and pollen.

Faced with a market shortage of mask materials

during the coronavirus outbreak, Sinopec decided

non-woven fabric production lines,

with four in Sinopec Beijing Yanshan Petrochemical Co.

and 12 in Sinopec Yizheng Chemical Fibre Limited.

It took only 76 days to construct

the world's largest meltblown non-woven fabric

production base from the commencement

on February 24 to full operation on May 9, 2020..

12 May 2020

Aramco announces first quarter 2020 results

First quarter net income: $16.7 billion

First quarter free cash flow*: $15.0 billion

Gearing* ratio of -4.9% reflects further strengthening

Dividends of $13.4 billion paid in the first quarter,

in respect of Q4 2019 Dividends of $18.75 billion

to be paid in the second quarter,

Low upstream costs and sustaining capital

provide significant flexibility

9 May 2020

China's leading energy and chemical company,

has put China’s largest petrochemical port

into operation with the successful docking

and unloading of the New Renown,

Crude Oil Tanker (VLCC) from the Middle East.

at the new 300,000-ton crude oil terminal

of Sinopec Zhongke Refinery Port,

the company’s industry-leading

“front terminal, rear plant” production model.

8 May 2020

Celanese Corporation has recently signed

for a long-term commercial agreement with

Anhui Wanwei Group Co., Ltd., (Wanwei),

Celanese’s green technology-based,

ethylene-based vinyl acetate monomer (VAM)

to support approximately 50 percent

of the company’s captive product

needs in the manufacture of chemicals, fibers,

and new material in Anhui Province, China.

Under the terms of the agreement,

the China Petroleum and Chemical Industry

an environmentally sustainable product.

(https://www.celanese.com/news-media/2020

/January/vam-green-technologyaward-china)

low content of heavy components

The designation by the CPCIF was listed in

the Directory for Petrochemical Green

7 May 2020

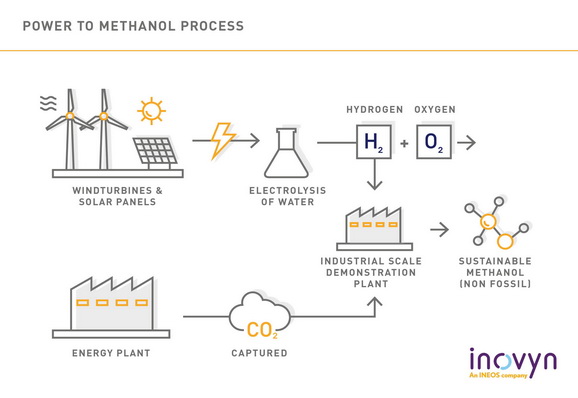

INOVYN to play vital role in ambitious

to produce sustainable methanol

Methanol is an essential multi-purpose raw material

for the chemical industry, with many applications

methanol is produced using fossil based raw materials,

which emits carbon dioxide from the process.

The new ‘Power to Methanol’ project at Antwerp,

being announced today, would produce

generated from renewable electricity.

A planned industrial-scale demonstration unit

would produce 8,000tpa of sustainable methanol

8,000tpa of CO2 emissions every year.

6 May 2020

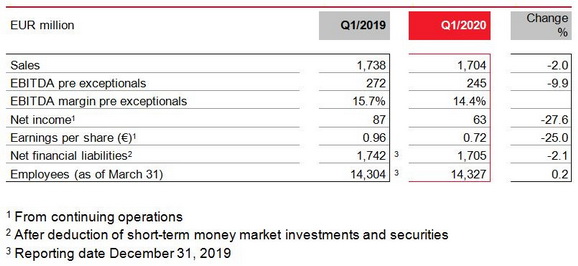

LANXESS robust in first quarter of 2020

Group sales amounted to EUR 1.704 billion

in the first quarter of 2020, down only slightly

on the previous year’s figure of EUR 1.738 billion.

Net income from continuing operation

declined by 27.6 percent from EUR 87 million

EBITDA margin pre exceptionals at 14.4 percent

Strong liquidity position increased

to around EUR 3 billion following Currenta sale

Guidance for full year adjusted:

EUR 800 million to EUR 900 million

6 May 2020

the world’s largest licensor of polyolen technologies,

Advanced Global Investment Company (AGIC)

has selected LyondellBasell’s leading

for a new world scale facility.

The process technologies will be used in

AGIC’s polyolen production assets

in Jubail Industrial City, Kingdom of Saudi Arabia.

using LyondellBasell’s benchmark

using LyondellBasell’s leading

6 May 2020

BASF's premium refinish brand, Glasurit®,

continues to be a recommended supplier

of paint solutions for BMW in 44 markets

around the world where the car company operates.

In 2020, Glasurit is approved for

refinish paint repairs of BMW and

Mini cars at all BMW authorized dealers

As part of the complete offer to BMW,

Glasurit offers a range of digital color management tools,

including the integrated Color Profi System.

Millions of color formulas can be reproduced quickly,

Glasurit's RATIO Scan 12/6 next generation

which precisely measures and optimizes

the color on the car and quickly and easily.

The markets and regions where BMW recommends

Glasurit automotive refinish paints

• Taiwan • Hong Kong • Thailand • Malaysia

• Singapore • Vietnam • Indonesia

CNOOC Huizhou Petrochemical Company Limited

Axens’ ParamaX® Technology Suite

for its petrochemical complex expansion

The project aims at increasing

CHPCL’s high-purity aromatics production capacity

The new aromatics complex will produce

1,500,000 tons per year of para-Xylene

Axens offered its second generation

of the energy-efficient ParamaX® Suite

of technologies for the cost-effective production of

para-Xylene, benzene and mixed xylenes

from aromatic-rich reformate and pyrolysis gasoline.

The ParamaX® Technology Suite is a combination

of top-of-the-line processes aimed at

the production of high-purity para-Xylene

and other aromatic molecules such as

meta-Xylene, ortho-Xylene, Benzene and Toluene.

>>DOWNLOAD AXENS PARAMAX BROCHURE

more than 30 ParamaX® aromatics complexes

and more than 400 process units

aimed at aromatics production or transformation..

4 May 2020

King Rama X's Coronation Day Anniversary

“I shall continue, preserve, and build upon

the royal legacy and shall reign with righteousness

for the benefit and happiness of the people forever,”

The king said in his first royal command

on May 4, 2019

The day of 4 May marks the coronation anniversary

of His Majesty King Maha Vajiralongkorn

the tenth monarch of the Royal House of Chakri,

1 May 2020

>>VIEW LYONDELLBASELL Q1 2020 PRESENTATION

LyondellBasell Reports First Quarter 2020 Earnings

Net Income: $0.1 billion, $0.5 billion excluding LCM

Diluted earnings per share: $0.42 per share,

EBITDA: $0.6 billion, $1.1 billion excluding LCM,

resilient performance in a challenging market

Launched production at our 500,000 ton U.S.

Gulf Coast high-density polyethylene plant

using LyondellBasell's next-generation

Expanding our presence in China

an integrated olens and polyolens joint venture

with Bora using LyondellBasell's polyolen technologies

Safely operating major facilities

as an essential industry supporting society's needs

CREDITS :

WEBSITES OF LEADING CHEMICAL,

PETROCHEMICAL, OIL AND GAS COMPANIES

and

WWW.SET.OR.TH,

WWW.BOI.GO.TH

MAY 2020

WWW.CHEMWINFO.COM BY KHUN PHICHAI

Glasurit® premium automotive refinish brand again confirmed as recommended supplier for BMW in 44 markets worldwide

.jpg)