World Chemical News, February 2020, by chemwinfo

27 February 2020

Methanex announces methanol contract price for

19 February 2020

Orocobre Agrees to Acquire Advantage Lithium Corp..

Orocobre shareholders will gain exposure to

the 4.8 million tonnes (Mt) of

Measured and Indicated Resources and

(expressed as lithium carbonate equivalent)

the Advantage and Orocobre joint venture

as detailed in the Orocobre ASX

14 February 2020

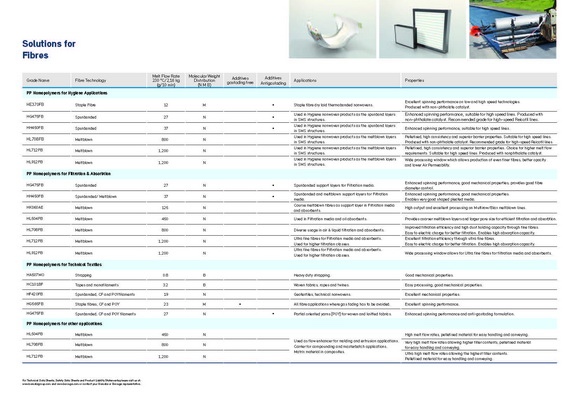

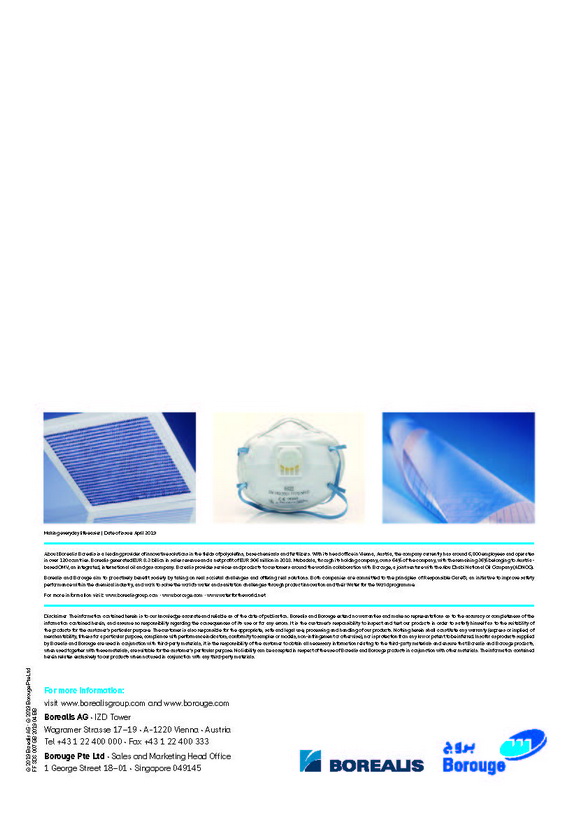

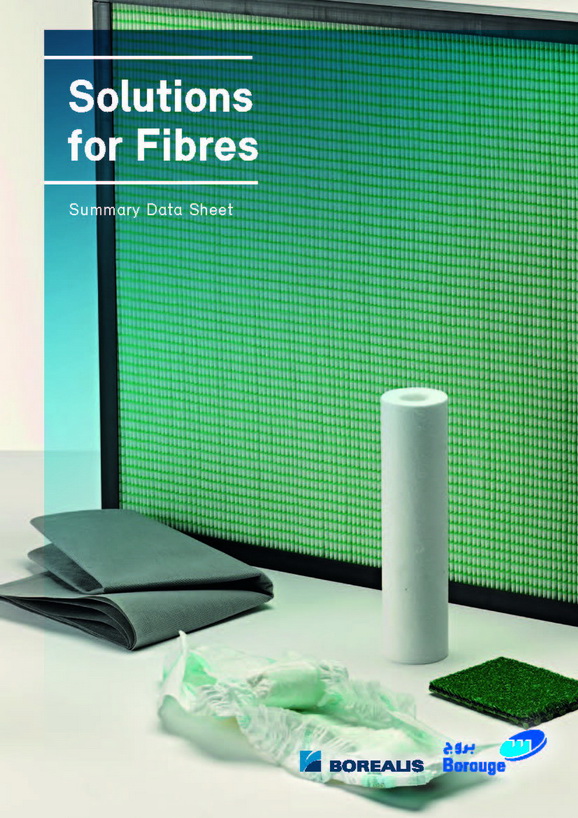

Using meltblown fibres in face masks

play a vital role in face masks.

This is where polymer innovators,

such as Borealis, are offering the optimised

meltblown polypropylene (PP) grades

featuring the dense material barriers

required to protect public health.

How meltblown fibres perform

* a layered laminate combination of

the coarser spunbond polypropylene (PP) fibres

** the very fine spun meltblown PP fibres (≈25 percent).

The functionality comes from the meltblown fibres,

which are just 1-2 microns in width.

To place their thin width into context,

just 4kg of meltblown PP fibres

placed in length would be enough material to reach the moon.

Innovation is continuing within this space, with Borealis taking it

to an even higher level with the 2017 launch of

an advanced meltblown fibre grade HL912FB,

which enables the production of even finer fibres

with greater barrier and filtration properties.

Application Development Engineer at Borealis

“This innovative material can be processed

at slightly higher temperatures (15-20°C)

which then leads to finer fibres.

This means more surface and an even denser web,

so the protection should be even better as a result,”

In Borealis laboratory trials, the HL912FB grade results

in a 25% improvement in quality factor (QF)

and an around 40% higher filtration efficiency,

when compared to reference grade polymer..

>>DOWNLOAD BOREALIS MELTBLOWN CATALOGUE

13 February 2020

Ineos partners with Forever Plast to

recycle over 6.5 billion bottle caps back

12 February 2020

BASF announces Schwarzheide, Germany,

as location for cathode active material production

This state-of-the art plant will produce

cathode active materials (CAM)

with an initial capacity enabling

the supply of around 400,000 full

The plant in Schwarzheide will use

from BASF’s previously announced plant

Startup of the two plants is planned for 2022..

Christine Haupt

BASF Corporate Media Relations

11 February 2020

INEOS and UPM Biofuels have today announced

to supply a renewable raw material

for new and innovative bio-attributed polymers

to be produced at INEOS Köln, Germany.

from a renewable residue of wood pulp processing,

to produce bio-attributed polyolens.

These new sustainable materials

will be used in a wide range of products

from plastic food packaging to medical and pipes.

the world’s first commercially available

bioattributed PVC, produced by

6 February 2020

Clariant continues to boost the supply

of high-quality activated bleaching earths

to the edible oil and biofuel markets

in Europe, the Middle East and Africa,

with additional capacity now on stream

and an extended portfolio of advanced

purification products for local customers..

• New product line extends portfolio

of highly activated bleaching earths

• Production & service closer to customers

in Spain of products

for 3-MCPD reduction in edible oils

Stefanie Nehlsen

Clariant Global Trade Media Relations

+41 61 469 63 63

6 February 2020

of innovative power storage technology..

JenaBatteries, which has developed

a so-called redox flow battery (RFB)

with organic materials, thus has

the world's first commercially available technology

Two liquid organic electrolytes

separated by a membrane and stored

in separate tanks store the current.

BASF will supply one of the two electrolytes

This battery material is based on an amine,

the company can produce on an industrial scale.

to market the first RFB in 2020..

5 February 2020

light industrial powder coatings manufacturer.

Founded in 2000, Alpha focuses on

the development, manufacture and sale

for light industrial applications;

and heat sensitive substrates;

and toll manufactures powder coatings

for metal and light industrial applications.

Alpha employs approximately 35 people

at its operations in West Chicago, Illinois..

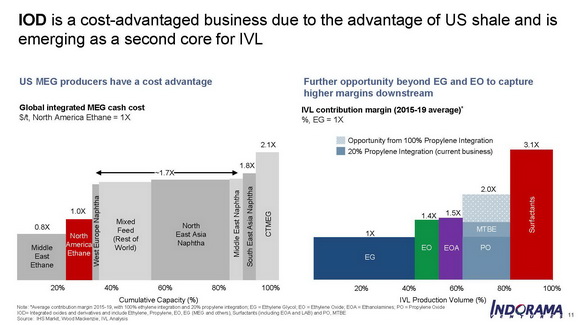

3 February 2020

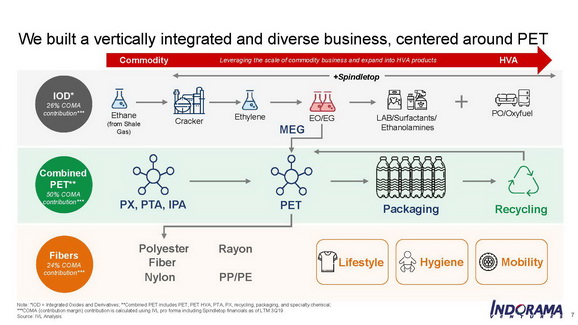

announce the commercial startup

of its olefins gas cracker plant at

Indorama Ventures Olefins LLC (IVOL)

in Westlake, Louisiana, USA on 31st January 2020.

The site has an ethylene production capacity

of 440 kilotons per annum (KTA) and

the US Gulf Coast ethylene pipeline infrastructure

The facility is strategically positioned

allows to leverage shale gas availability

for a long-term captive ethylene supplies to

Indorama Ventures (Oxide and Glycols) LLC

(IVOG) plant in Clear Lake, Texas

CREDITS :

WEBSITES OF LEADING CHEMICAL,

PETROCHEMICAL, OIL AND GAS

COMPANIES AND ORGANIZATIONS

as well as

WWW.SET.OR.TH,

WWW.BOI.GO.TH

FEBRUARY 2020

WWW.CHEMWINFO.COM BY KHUN PHICHAI