14 March 2019

ABOUT JIANGSU SAILBOAT PETROCHEMICAL

Jiangsu Sailboat Petrochemical Co., Ltd.

is a wholly-owned subsidiary company of

Shenghong Holding Group located in

Xuwei new district Industrial Park,

Lianyungang City, Jiangsu province.

When fully completed, the Sailboat olefins complex

will produce more than 2.5 million tons

of short-supply high-end petrochemical products annually.

DETAILS

Honeywell (NYSE: HON) announced today that

Jiangsu Sailboat Petrochemical Co., Ltd.

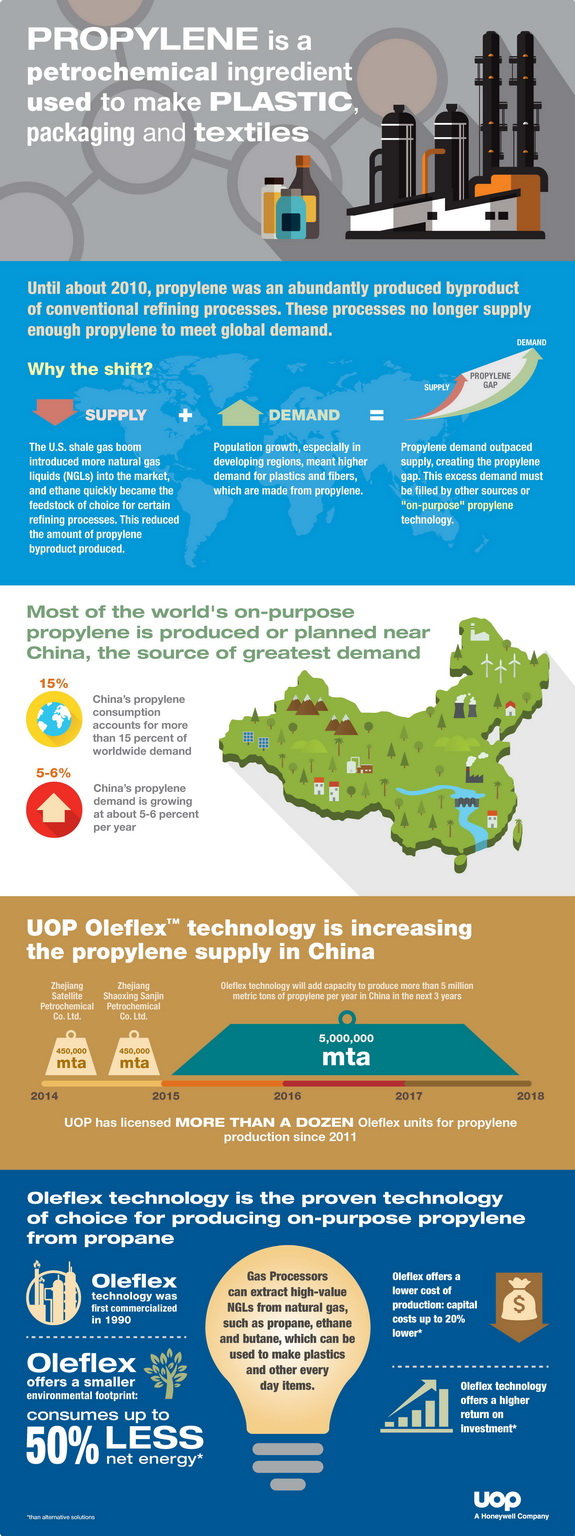

will use Honeywell UOP’s C3 Oleflex™ technology

to produce 700,000 metric tons per year of

polymer-grade propylene

at its facility in Lianyungang City

in China’s Jiangsu Province.

Jiangsu Sailboat will expand its existing facility,

which uses

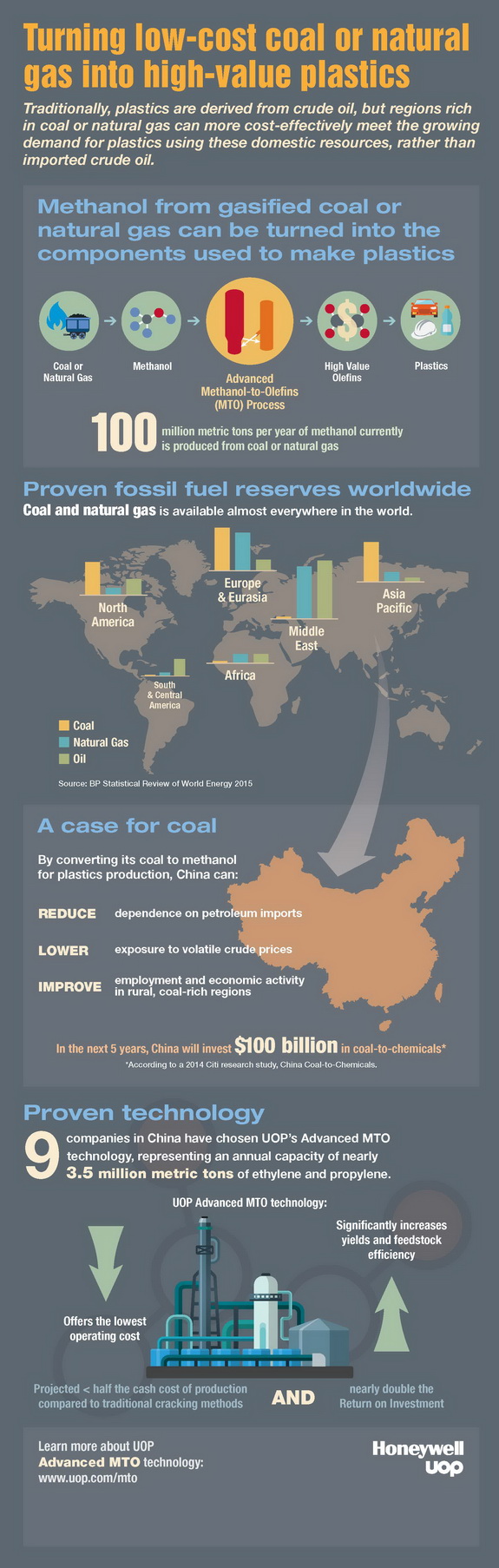

Honeywell UOP’s methanol-to-olefins (MTO) process

to produce ethylene and propylene.

The facility’s additional output of propylene

will further help China meet its demand for plastics

used to make a wide range of consumer goods.

Honeywell UOP will provide

licensing and a process design package,

equipment, on-site operator training, technical services,

and catalysts and adsorbents for the project.

Honeywell UOP’s C3 Oleflex technology

uses catalytic dehydrogenation

to convert propane to propylene.

Its low-energy consumption, low-emissions and

fully recyclable, platinum-alumina-based catalyst system

helps minimize its impact on the environment.

It is designed to have a lower cash cost of production

and higher return on investment

compared to other technologies.

The independent reaction and regeneration sections

enable steady-state operations, improved operating flexibility

and a high on-stream factor and reliability.

Honeywell UOP also licenses C4 Oleflex technology,

which converts isobutane to isobutylene,

the primary ingredient for making

high-octane fuel additives and synthetic rubber.

Including this project, Honeywell UOP’s Oleflex technology

has been selected for a majority of

propane and isobutane dehydrogenation projects

globally since 2011.

The agreement with Jiangsu Sailboat

marks Honeywell’s 36th award in China

for its proprietary Oleflex technology.

Since the technology was first commercialized

nearly 30 years ago, UOP has commissioned 31 Oleflex units

for on-purpose propylene and isobutylene production.

Global production capacity of propylene

from Oleflex technology

now stands at approximately 7.3 million metric tons per year

Bryan Glover,

vice president and general manager of

Honeywell UOP’s Process Technology and Equipment business

“As demand for propylene derivatives for consumer products

in China continues to rise, UOP’s Oleflex technology

provides greater energy and cost efficiency than

other propane dehydrogenation technologies,”

“Customers such as Jiangsu Sailboat also find

the technology to be environmentally preferable

and provide a higher return on investment.”

Global media contact:

John Simley

+18473912278

john.simley@honeywell.com

China media contact:

Emily Deng

+8618221436771

Jingyin.deng@honeywell.com

WWW.CHEMWINFO.COM BY KHUN PHICHAI