28 January 2019

ABOUT CID

What is CiD?

Continuous Initiator Dosing (CiD) is a revolutionary concept

which increases your PVC production capacity by 20-40%

while making your process intrinsically safer.

In addition to improving your product consistency and quality,

CiD can simultaneously reduce your costs.

CiD has already been implemented successfully

at several production locations around the world.

How does it work?

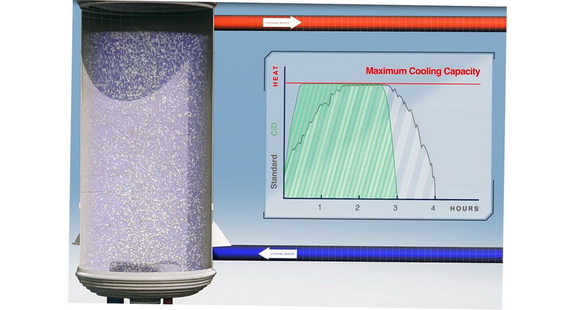

In traditional PVC production, in the first step of the process,

the reactor is loaded with the raw material VCM and water.

Then the total amount of organic peroxides needed

for the polymerization is added.

The temperature is increased and

the peroxides initiate the polymerization reaction.

During the reaction, a lot of heat is produced

and the capacity of the reactor

is determined by the maximum cooling capacity.

With our officially licensed CiD, the heat production in the reactor

is controlled by the dosing of the peroxide

throughout the polymerization process.

To achieve this, a control valve is installed

and a special fast peroxide, Trigonox® 187, is used.

Now the cooling capacity is optimized

and the batch time is reduced by 20-40%,

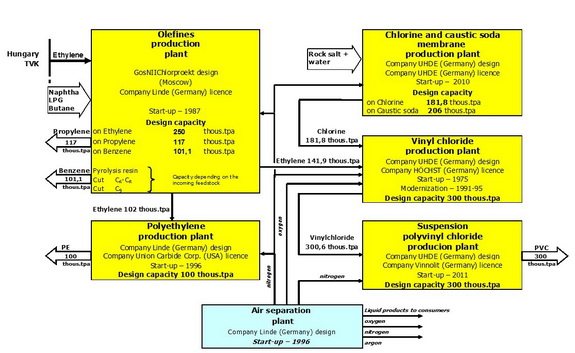

Suspension polyvinychloride production unit

Plant capacity: 300 000 tpa.

Year of start-up – 2011.

Process developer : Company Vinnolit, Germany.

Design: company Uhde, Germany.

Production process technology consists of the following units :

Cold and hot demineralized water storage;

Fresh and recovery vinylchloride (VCM) and (R-VCM) storage;

Chemicals dissolving and preparation;

Vinylchloride polymerization (two parallel lines with two reactors in each.

Polyvinychloride suspension degassing (two parallel lines).

Unreacted vinylchloride recovery.

Polyvinychloride suspension centrifuging and drying (two parallel lines).

Finished products storage and bagging.

Waste water treatment

Demineralized water production unit.

Cooling tower with a pump house.

Principal products: suspension polyvinyl chloride.

DETAILS

Nouryon (formerly AkzoNobel Specialty Chemicals)

will license its

innovative continuous initiator dosing (CiD) technology

to Karpatnaftochim,

Ukraine’s largest polyvinyl chloride (PVC) producer.

Nouryon’s patented CiD technology allows PVC producers

to increase reactor output by up to 40 percent,

improve product quality,

and make the production process intrinsically safer

– all with minimum capital expenditure.

In conventional PVC production,

the organic peroxide initiator is added in one step –

this generates a lot of heat and the reactor output

is determined by the cooling capacity.

With CiD technology, the initiator is added continuously,

reducing the amount of heat produced,

making the process safer and increasing

the effective capacity of the reactor.

Johan Landfors,

Managing Director Polymer Chemistry

“The agreement with Karpatnaftochim once again

confirms our strong offering to customers in the PVC market,”

“Many customers have made the shift to CiD technology,

and we expect interest for this technology

to continue to grow as more users realize its advantages.”

Ivan Pidsadyuk,

General Director of Karpatnaftochim

“Nouryon’s CiD technology introduces unique benefits for us

and our customers.

As an important manufacturer in a competitive market,

we aim to incorporate solutions that give us an advantage.”

WWW.CHEMWINFO.COM BY KHUN PHICHAI