6 December 2018

OUR VISION

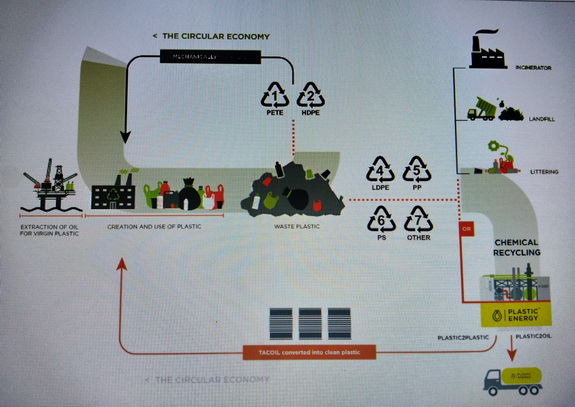

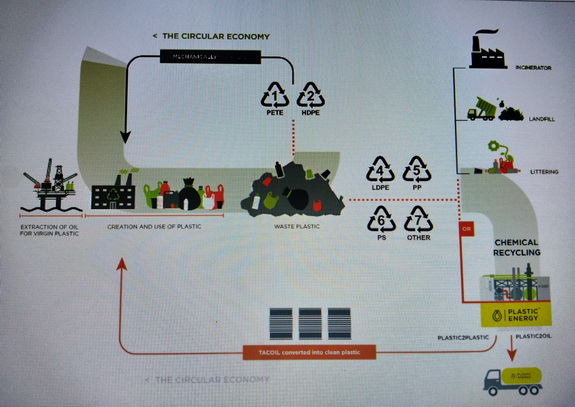

- Creation of a circular economy of plastic (Plastic2Plastic)

by diverting plastic waste away

from landfills and our oceans - Reduce the dependence of countries

on fossil fuel imports - Support countries in reaching recycling targets,

reduce CO2 footprint,

and reach international sustainability goals - Boost local economies and communities

through the creation of new jobs

We offer a global solution to help everyone

prevent plastic pollution, by transforming

previously unrecyclable plastic waste

into a valuable resource.

Our patented, low carbon footprint technology

converts valueless plastic waste into alternative fuels,

or oil (TACOIL) for making new virgin (foodsafe) plastics,

closing the plastic loop

and creating a circular economy.

A Global Company

Waste plastic is a global concern and Plastic Energy

is able to adapt to fit local requirements,

simultaneously working with international and local partners

to efficiently expand the technology worldwide

to help prevent plastic pollution.

The use of plastics has increased twentyfold

in the past half-century and is expected

to double in the next 20 years.

Although some of this plastic can be mechanically recycled,

a large portion is composed of contaminated

and low-value plastics that cannot and end up

being incinerated, buried in landfills, or polluting our oceans.

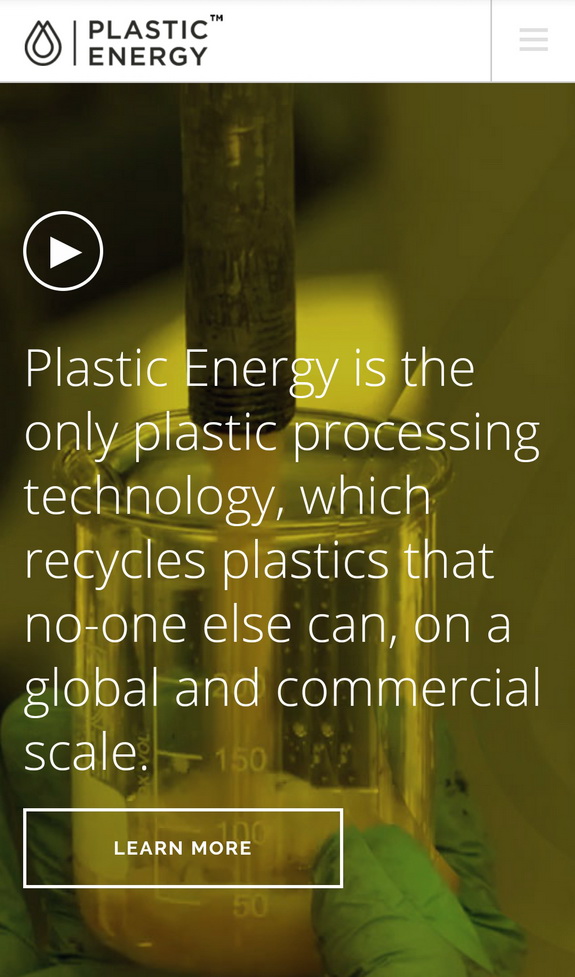

We are the only technology which can process

and convert end-of-life or contaminated plastics

that no-one else can.

Modular plants

Plastic Energy's modular plants can be built anywhere

and integrate with existing infrastructure and processes.

Industry leaders

We are the global leader in chemical plastic recycling

with proven, scalable patented technology

and the capability of successfully

and continously processing plastics.

Patented technology

Our UK based team of technology specialists

have over 50 years' combined experience developing

the patented thermal anaerobic technology (TAC) process,

converting valueless plastic waste into to oil

and back into virgin plastic,

suitable for foodsafe use (Plastic2Plastic).

Benchmarking

We are benchmarking our plants in Seville and Almeria

and always looking for ways to improve production

in a ground-breaking and environmentally friendly way.

Plastic Energy LTD Contact

London

info@plasticenergy.com

ADDRESS

Innovation Centre

Here East London E20 3BS

PHONE

+ 44 203 146 4967

DETAILS

SABIC has today announced

it has signed a memorandum of understanding (MoU)

with UK-based PLASTIC ENERGY Ltd.,

a pioneer in chemical plastics recycling,

for the supply of feedstock

to support SABIC’s petrochemical operations in Europe.

SABIC and PLASTIC ENERGY intend to build

a first commercial plant in the Netherlands

to refine and upgrade a valuable feedstock,

known as TACOIL,

a patented PLASTIC ENERGY product,

which will be produced from the recycling of

low quality, mixed plastic waste otherwise

destined for incineration or landfill.

The plant, which is anticipated

to enter commercial production in 2021,

is a significant milestone for SABIC

towards the company’s commitment

to establishing a circular economy

and, more broadly, its sustainability goals.

PLASTIC ENERGY has successfully commercialised

a patented thermochemical conversion technology

to convert a wide range of end-of-life, dirty

and contaminated plastics, hardly recyclable

for conven-tional processes, into usable feedstock.

Plastics are melted in an oxygen free environment

and then broken down into synthetic oils

at which point the oils need to be refined and upgraded

as feedstock for traditional petrochemical uses.

Frank Kuijpers,

General Manager for Corporate Sustainability, SABIC

“Sustainability is a core value at SABIC

and the circular economy is a cornerstone of our strategy

as evidenced by this unique agreement”

“SABIC is proud to be the first petrochemical company

to implement a project

for the chemical recycling of challenging plastic waste

into feedstock for steam crackers.

This exciting project is testament to our commitment

to scale up advanced chemical recycling processes

of plastics back to the original polymer."

Carlos Monreal,

Founder and CEO of PLASTIC ENERGY

“We are delighted to be working with SABIC

on this exciting project

to support their petrochemical operations in Europe”,

“We have already two industrial plants in Spain

operating 24/7 and a technology team

with more than 10 years of experience

developing this patented technology.

Our advanced expertise will promote this new opportunity

to turn plastic back into plastic

as part of the circular economy.”

WWW.CHEMWINFO.COM BY KHUN PHICHAI