26 November 2018

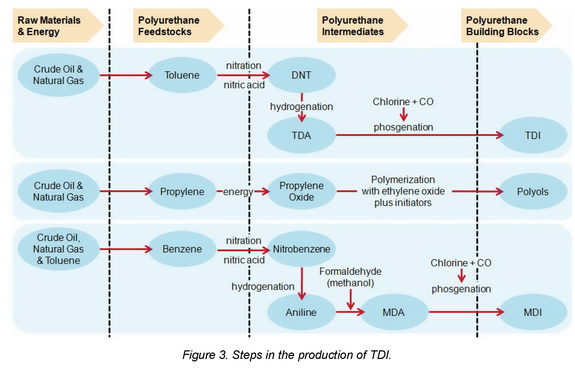

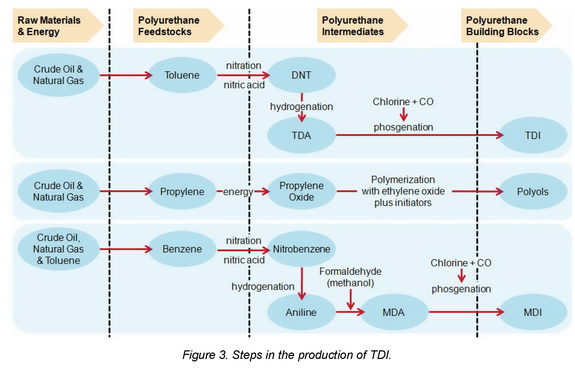

TDI Production Process In the TDI process,

toluene diamine (TDA) is manufactured by

the catalytic reaction of dinitrotoluene (DNT).

TDA is in turn reacted with phosgene (carbonyl chloride)

to produce toluene diisocyanate (TDI).

Figure 3 gives a view of the production steps to produce TDI.

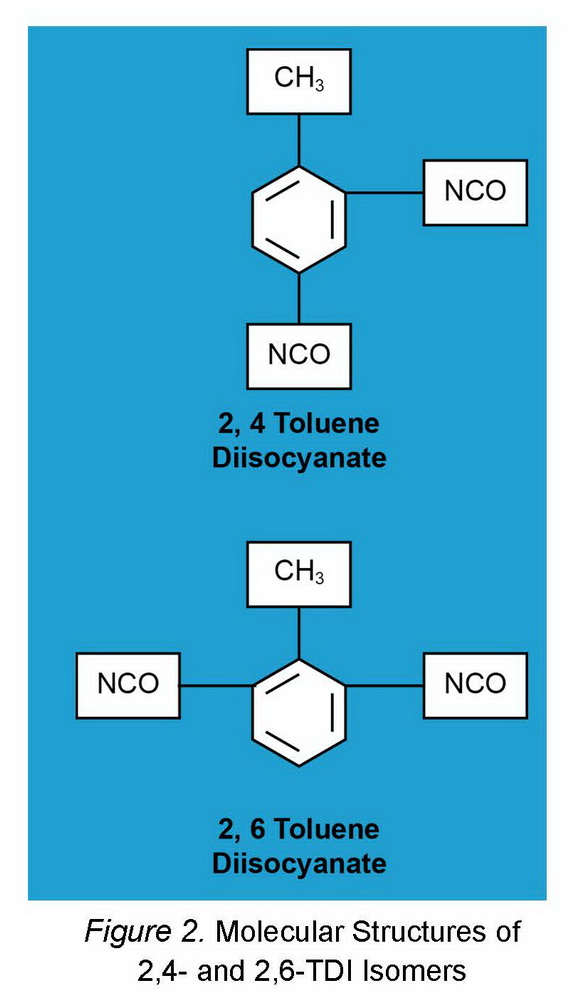

BASF TDI is an 80:20 mixture of

the 2,4-and 2,6-TDI isomers assaying 99.5% TDI minimum.

TDI is produced in a number of grades

that differ slightly in acidity and hydrolyzable chloride content.

Increased acidity of TDI allows broader processing latitude

in some applications.

Type I is used in flexible slab polyurethane foam and

Type II is used primarily in coating, adhesive, sealant,

and elastomer (CASE) applications

wherever an intermediate prepolymer is produced.

Properties of TDI

TDI is more dense than water and will sink to the bottom

of waterfilled containers.

Although it reacts exothermically with water,

the rate of reaction is very slow at temperatures

below 50°C (122°F).

At higher temperatures the reaction becomes progressively

more vigorous and can be violent.

The reaction of TDI with water forms both

carbon dioxide (CO2) and insoluble polyurea compounds.

Even small quantities of water may produce s

ufficient CO2 to rupture sealed containers.

DETAILS

The water level of river Rhine

is currently on an all-time low,

impacting transport by ship.

Despite maximum shift to alternative means of transport

(pipeline, trucks and rail), not all raw materials

can be supplied to BASF’s Ludwigshafen site.

Steps in the production of TDI

Therefore, BASF will have

to stop the TDI production in Ludwigshafen.

Restart of production depends on

improved Rhine water level.

BASF is in close contact with its customers.

Receive the latest press releases from BASF

via WhatsApp on your smartphone or tablet.

Register for our news service

Media Relations

Daniela Rechenberger

Phone: +49 621 60-20916

daniela.rechenberger@basf.com

WWW.CHEMWINFO.COM BY KHUN PHICHAI