18 October 2018

ABOUT THYSSENKRUPP INDUSTRIAL SOLUTIONS

DOWNLOADS PLA TECHNOLOGY BROCHURE

Details

To reduce reliance on petroleum-based plastics,

thyssenkrupp has developed

a manufacturing process

for the bioplastic polylactide (PLA).

The world’s first commercial plant based on

the patented PLAneo® technology

recently started production in Changchun, China.

It is operated by the

Jilin COFCO Biomaterial Corporation,

a subsidiary of COFCO,

China’s largest food and beverage group.

The new plant produces all standard PLA types,

among other things

for the production of eco-friendly packaging,

fibers, textiles and engineering plastics.

Sami Pelkonen,

CEO of the Electrolysis & Polymers Technologies

business unit of thyssenkrupp Industrial Solutions

“The bioplastics market will continue to grow

in the coming years, not least due to

the increasing environmental awareness of industry,

governments and consumers.

With our PLAneo® technology we want to do our bit

to make the plastics sector more sustainable

and resource-friendly.

With it we enable our customers

to produce high-quality bioplastics

with a wide range of properties

– at a price that is competitive with conventional plastics.”

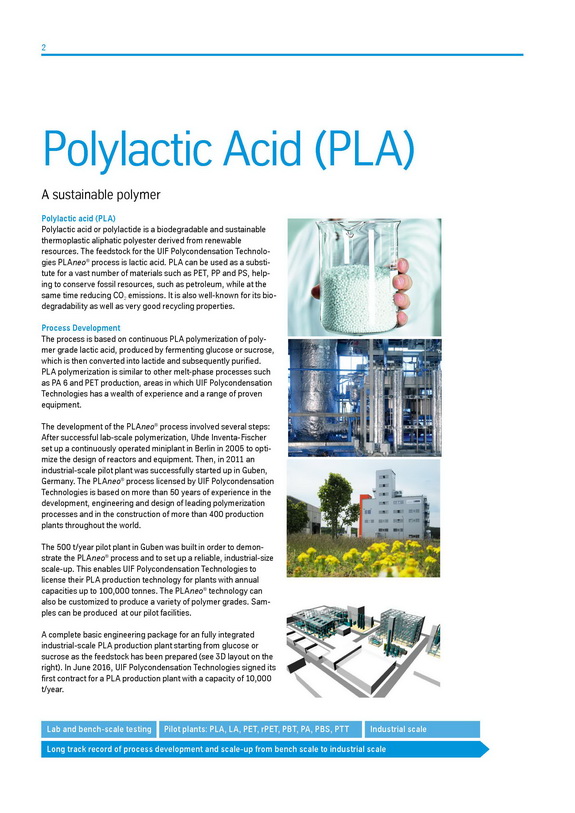

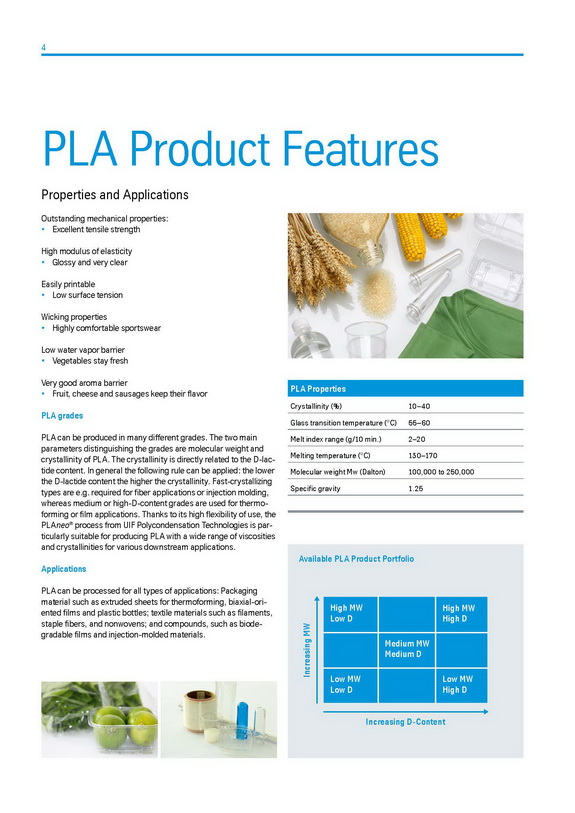

Polyactide (PLA) is a 100% bio-based and compostable plastic

which thanks to its physical and mechanical properties

can replace conventional oil-based polymers in many areas.

The starting material for PLA production is

lactic acid,

which is recovered from renewable resources

such as sugar, starch or cellulose.

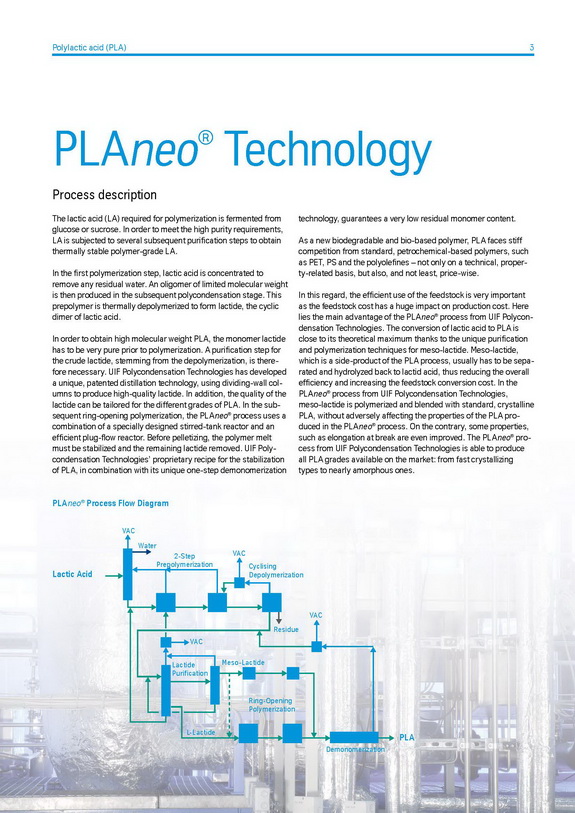

PLAneo® technology converts lactic acid into PLA

in a particularly efficient and resource-friendly way.

Another advantage is its transferability to large-scale plants

with capacities of up to 100,000 tons per year.

In developing the technology, thyssenkrupp’s subsidiary

Uhde Inventa-Fischer

profited from decades of expertise gained from

the construction of more than 400 polymerization plants

and extensive experience in the scale-up of new technologies.

For the new plant in Changchun thyssenkrupp provided

* the engineering,

* key plant components and

* supervision of construction and commissioning.

Isabel Reinhardt

External Communications

Telephone: +49 201 844 535472

Send emailWWW.CHEMWINFO.COM BY KHUN PHICHAI