29 August 2018

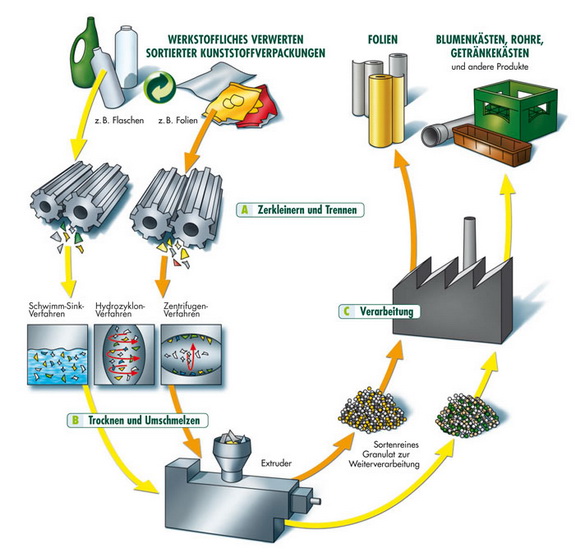

Plastic packaging is collected and sorted

by households and businesses.

This waste is collected by a waste disposal company

and then a sorting company sorts it into

individual ‘fractions’ or types.

In the case of plastics this might be

LDPE, HDPE, PVC, PET etc.

The different fractions are processed by recycling companies or,

in industry, incinerated.

Material recycling companies like Ecoplast ensure that

the sorted plastic waste is turned into new raw materials again.

These raw materials are then used to make new plastic products,

which may be wholly or partly composed of recycled material.

DETAILS

Borealis announces today that it has fully acquired

the Austrian plastics recycler

Ecoplast Kunststoffrecycling GmbH (“Ecoplast”).

Based in Wildon, Austria, Ecoplast processes

around 35,000 tonnes of post-consumer plastic waste

from households and industrial consumers every year,

turning them into

high-quality LDPE and HDPE recyclates,

primarily but not exclusively for the plastic film market.

The expectation of Borealis is that

the recycled PO market

will grow substantially by 2021,

which is the strategic rationale behind the acquisition.

The company has made PO recycling

a key element of its overall PO strategy

because of its potential to support

both growth and sustainability.

Borealis has been an industry frontrunner

in making polyolefins more circular.

In 2014, it began offering high-end compound solutions

to the automotive industry,

consisting of 25% and 50% post-consumer recycled content.

Borealis was also the first virgin PO producer

to explore the possibilities of mechanical recycling,

by acquiring one of Europe's largest producers

of post-consumer polyolefin recyclates

- mtm plastics GmbH and mtm compact GmbH – in July 2016.

Since then it has continued to invest

into the development of technology

and new products in the area of circular polyolefins.

Alfred Stern

Borealis Chief Executive

“Borealis recognises the increasing need for plastic recycling

and sees

the Circular Economy

as a business opportunity.

Borealis already has a long-term collaboration

with Ecoplast and this acquisition

is the next logical step in building

our mechanical recycling capabilities.

As an important complement to mtm in Germany,

Ecoplast will help us address critical sustainability challenges

and become a polyolefin recycling leader.

Eventually, we want to use our experience to develop

an effective blueprint for the end-of-use phases

for plastics that can be applied in other parts of the world,”

Lukas Intemann

Ecoplast’s Managing Director

“We are very happy that the transaction

with a strong and reliable partner

such as Borealis has been successfully concluded

and are looking forward to our common future activities

on the recycling market.

We have located potential synergies

in many operative and strategic areas,

especially in product quality R&D

and future applications of polyethylene-film-recyclates.

The combination of Ecoplast and Borealis

holds the potential to be groundbreaking for the market,”

For further information, please contact:

Patrick Laureys

Senior External Communications Manager

tel.: +43 1 22 400 726 (Vienna, Austria)

WWW.CHEMWINFO.COM BY KHUN PHICHAI