24 July 2018

Jesper Fahlen

DETAILS

Perstorp recently reported that

they have made significant progress in

‘future-proofing’ its Capa™ caprolactone monomer plant

in Warrington, United Kingdom.

The monomer plant will be made more robust

to ensure an even more reliable supply

for customers around the world.

This investment will also facilitate future debottlenecking

to support market growth. Perstorp is building

in the capability for the plant to run with a higher capacity,

which allows for increased production volumes in the future.

In addition, Perstorp is now starting

to debottleneck its Capa™ derivatives production units

at Warrington, UK to further support customer demand.

Stephen Lewis,

Vice President Business Unit Caprolactones

“We continue to see strong confidence and demand

in the caprolactone market, and in particular

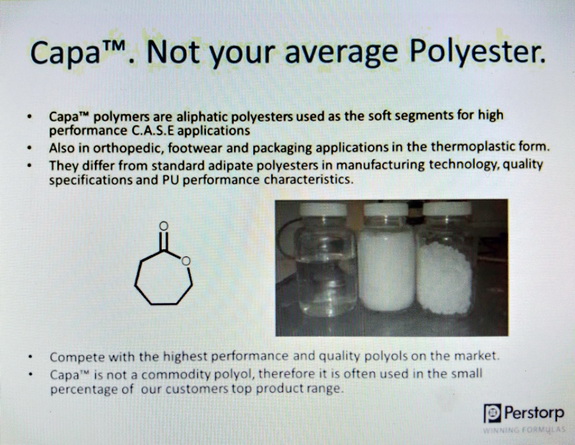

for our range of caprolactone derivatives marketed

under the names Capa™ Thermoplastics and Capa™ Polyols.

In order to provide high quality products and a partnership

that strengthens our customers’ businesses,

we strive to increase even further

the reliability of manufacturing and supply aimed at the market”,

“In particular, the strong growth is largely driven

by our customers’ recognition of

the unique properties and performance advantages

of our Capa™ product range.

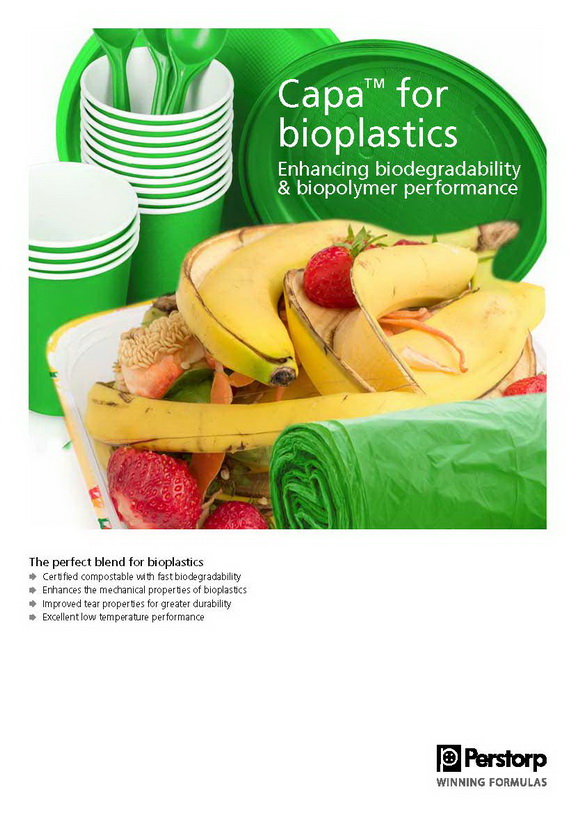

Capa™ Thermoplastics are utilized in diverse application areas

such as

Adhesives and Sealants, Medical, Bioplastics and Footwear.

An increasing demand leads to a strong need

to invest in additional capacity, in order to ensure

we meet our customer’s future requirements

and growth plans in a timely manner”.

Stephen Lewis

WWW.CHEMWINFO.COM BY KHUN PHICHAI