20 June 2018

DETAILS

BP and Xin Feng Ming Group Co., Ltd. (Xinfengming)

license BP’s latest generation

purified terephthalic acid (PTA) technology

to Dushan Energy Ltd.,

a subsidiary of Xinfengming.

BP and Xinfengming also signed

a memorandum of understanding (MOU)

to deepen strategic cooperation

along the polyester raw materials value chain

and Xinfengming intends to deploy BP technologies

for all Xinfengming’s future PTA and related investments.

Dushan Energy Ltd. intends to build

a 2.2 million tonnes per annum unit

at Dushan Port Economic Development Zone

in Pinghu, Zhejiang province.

At present, the basic design of the PTA unit

has been completed and construction has started on the site.

The project is expected to commence production in Q3 2019.

The MOU on strategic cooperation covers

Xinfengming’s further investments in PTA phase II

utilizing BP’s most advanced PTA technologies

and related products.

In addition, based on China's move towards products

with improved environmental performance,

BP and Xinfengming will jointly promote

low-carbon products in China.

Zhuang Kunlong,

Chairman of the board of directors of Xinfengming

“We recognize the advantages of BP’s cutting-edge PTA

and related technology and its innovative capability

in the polyester supply chain.

We hope that working collaboratively with BP in these areas

will further enhance Xinfengming’s competitiveness

in the polyester industry in the long run.”

Dr. Xiaoping Yang,

BP China president,

“We are committed to supporting

the sustainable development of China’s petrochemicals industry

through our most advanced PTA technologies and expertise,”

“Through the MOU, BP and Xinfengming will jointly

deliver high-quality products to customers.”

Rita Griffin,

chief operating officer,

BP Petrochemicals

“We are delighted to provide

our most advanced PTA technology

to Xinfengming, one of the leading enterprises

in China’s chemical fibre industry.

Combining BP’s technology and brand with

Xinfengming’s long experience

in the China polyester industry

we expect to pave a solid foundation

for future collaboration and mutual development

for both parties.”

Based on internal comparisons of

conventional PTA technology with

BP's latest generation of PTA technology,

there are significant reductions

in both operational costs and capital costs,

leading to high investment returns.

BP’s technology is also renowned for

its significant environmental performance

with several Chinese government awards granted

since Zhuhai start-up in 2003.

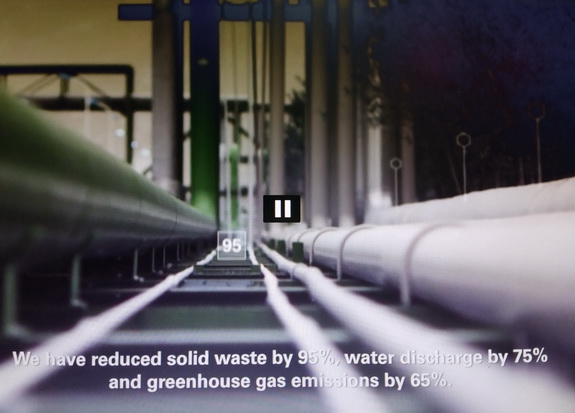

Through our research and development efforts,

we introduced a latest generation PTA technology

in our Zhuhai plant that delivered

65% fewer GHG emissions,

75% less water discharge and

95% less solid waste disposal

in its manufacturing process than

the manufacturing process

for conventional PTA technology of the 1990s[1].

[1] Derived from BP’s internal analysis Evaluating Energy

Processing Technology, conducted in 2016.

Data in this internal analysis was derived from

BP’s actual operating data

from six of its PTA manufacturing facilities.

Further information

BP press office,

London: +44 (0)20 7496 4076,

bppress@bp.com

BP press office,

China: +86 (0)10 6589 3878,

bpchinapress@bp.com

WWW.CHEMWINFO.COM BY KHUN PHICHAI