23 January 2017

DETAILS

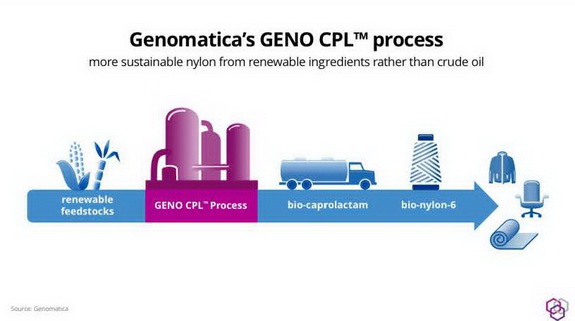

Aquafil and Genomatica have announced

a multiyear agreement to create

sustainable caprolactam,

a key ingredient

to producing 100 percent sustainable nylon.

The collaboration aims to develop

a commercially-advantageous bioprocess

(Genomatica’s GENO CPL™ process)

to make caprolactam

using plant-based renewable ingredients,

rather than the crude oil-derived materials

traditionally used by the nylon industry.

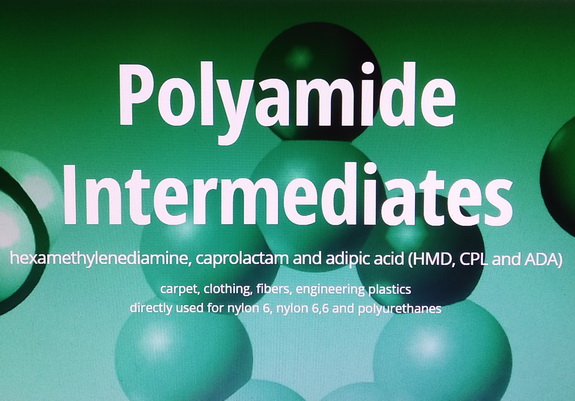

Enabling more sustainable nylon products Used

in a variety of nylon-based products

including carpets and apparel,

caprolactam has a worldwide market

of over five million tons per year.

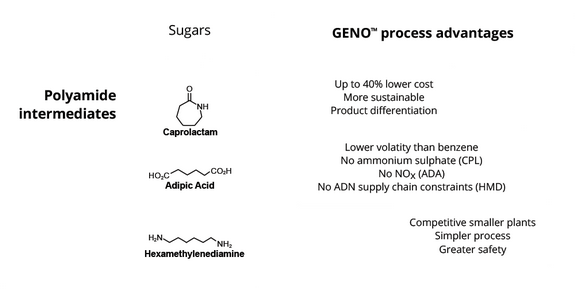

Genomatica’s GENO CPL™ process aims to provide

an environmentally-friendly way

to make caprolactam with better economics,

including for smaller-scale plants.

Additionally, it will enable licensees and their customers

to differentiate themselves by offering

a more sustainable bio-based product

whose performance will be fully comparable with nylon

made from crude oil-derived caprolactam,

and which will not require any machine or process adjustments

by the nylon supply chain.

Genomatica is the licensor of the GENO CPLTM process.

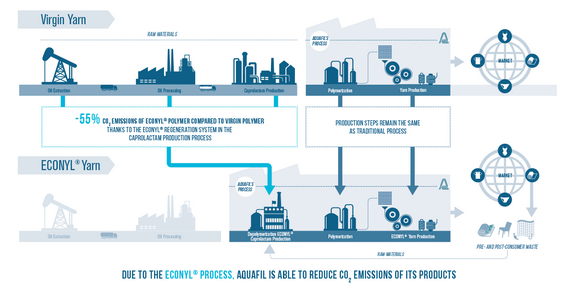

Aquafil is a leading producer of nylon yarn and launched

the ECONYL® Regeneration System in 2011

to produce nylon made from 100 percent regenerated waste.

A large and growing number of globally recognized sportswear,

fashion, luxury and carpet brands choose ECONYL®

as the sustainable ingredient for their product.

Like the ECONYL® process, the GENO CPL™ process

eliminates the significant amount of by-products common

to most crude oil-derived caprolactam production,

and will allow producers to diversify their sources

in terms of raw material.

For more information:

For Aquafil:

Maria Giovanna Sandrini,

maria.giovanna.sandrini@aquafil.com

For Genomatica:

Steve Weiss,

sweiss@genomatica.com,

+1.858.210.4424

WWW.CHEMWINFO.COM BY KHUN PHICHAI