20 July 2017

DETAILS

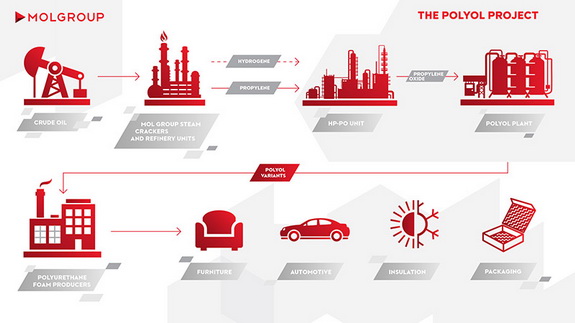

The Polyol Project will be the largest investment project

of MOL Group in 2017-21

MOL Group will move further along

the petrochemical value chain

towards semi-commodity and specialty chemicals products

as part of its 2030 strategy

MOL will become the only integrated polyol producer in CEE

Half a year after the announcement of the 2030 strategy,

MOL Group has reached an important milestone

in its industrial transformaonal journey.

The license agreements signed with Evonik and thyssenkrupp,

will enable MOL to produce propylene oxide,

a key component for the production of polyether polyols.

MOL intends to become a significant producer of polyether polyols,

high-value intermediates for products applied

in the automove, packaging and furniture industries.

MOL Group has entered into key contracts

related to core technologies of the Polyol Project,

which was announced in 2016 as part of

the first investment cycle of the MOL 2030 long-term strategy.

The contracts concern

* the purchase of technology licenses and

* process design packages

for the so called

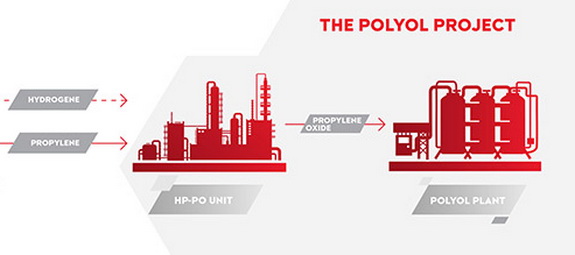

HPPO (hydrogen peroxide to propylene oxide) technology

of propylene oxide producon.

* The licensor of the hydrogen-peroxide unit

for captive use is Evonik,

* while a consortium formed by

Evonik and thyssenkrupp Industrial Soluons

licenses the propylene oxide unit.

The contracts also contain

* binding offers and pre-agreements regarding

the later engineering and execuon phases of the HPPO units

by thyssenkrupp and

* the purchase of proprietary catalysts from Evonik.

The signing of these license contracts

marks the beginning of this major investment project

that is of strategic importance for MOL,

as well as the beginning of a longterm partnership

between MOL Group, Evonik and thyssenkrupp.

In addion, MOL Group has selected

Fluor as Project Management Consultant (PMC)

* for the front end engineering design and

* engineering, procurement and construcon phases of the project.

MOL Group is in the final stages of

* selecting the licensor for polyether polyol technology

as well as

* the contractor for the engineering

of the utilies and other facilities.

These agreements represent the first milestone

in the execuon of the MOL 2030 long-term strategy,

which earmarked around USD 1.9bn in investments

for transformaonal projects

in the area of chemicals and petrochemicals

for the period of 2017-21.

The industrial complex,

which will be built in Hungary,

will be the single largest organic investment project

of MOL Group in 2017-21.

The new product line will not only provide access to

attractive markets in the CEE, but it will also

form a logical continuation of MOL’s strategy

to move further along

the Downstream value chain

towards semi-commodity and specialty chemicals products.

In line with MOL’s core value of sustainable development,

this step has taken MOL closer

to a state-of-the-art, energy-efficient technology

that is free of material by-product volumes.

Propylene oxide based polyols

serve as raw materials for polyurethane foams,

which are widely applied in the automove, construcon,

packaging and furniture industries.

The planned new industrial complex consists of

the HPPO plants having

200 kt/year propylene oxide production capacity,

several producon lines for polyether polyols,

utilities and other infrastructural investments.

Zsolt Hernádi,

MOL Group Chairman-CEO

"Today’s agreement with our renowned partners

marks an important step in

the implementaon of the MOL Group 2030 strategy,

which will transform MOL Group into

the leading chemical company in CEE.

As a first decisive investment step, we will spend

up to USD 1 billion on the Polyol Project

and thus become a significant European player.

The innovative and environmentally friendly technology

will not only enable us to become

the only integrated polyol producer in our region,

but will also be a doorway to

enter other, highly profitable areas of the chemical industry.

Johannes Ohmer,

Member of the Board of Management

of Evonik Resource Efficiency GmbH,

“The Polyol Project is a good example

where strong partners combine their specific strengths

to powerfully and successfully join forces

and in doing so building the foundaon

for a long-lasting and trustful strategic partnership.

Evonik will contribute with

its advanced technology know-how

and operation experience as well as

the outstanding performance of its proprietary catalysts.

As an innovave and reliable partner

we stand for resource-efficient and thus sustainable solutions.

Sami Pelkonen,

CEO of the Electrolysis & Polymers business unit

at thyssenkrupp Industrial Solutions

“We are proud to enter into this long-term license agreement

which will allow MOL to produce high-quality propylene oxide

through an extremely cost-effecve process.

The process, which offers efficient feedstock consumpon,

environmentally-friendly producon and low capital investment,

was developed based on our strong experse

in process engineering and the design

and construcon of chemical and

other industrial plants jointly with our partner Evonik.”

MOLGROUP Media Contact

DOMOKOS SZOLLÁR

Vice President, Corporate Communicaons

Phone: +36 1 464 1772

TAMÁS BERZI

Head of Media Relaons

Phone: +36 20 409 7632

Email: tberzi@mol.hu (mailto:tberzi@mol.hu)

ANNA WIŚNIOWSKA

Media Relaons Officer

Phone: +36 20 243 3963

Email: awisniowska@mol.hu (mailto:awisniowska@mol.hu)

WWW.CHEMWINFO.COM BY KHUN PHICHAI