3 December 2015

DETAILS

Mitsubishi Chemical Holdings Group companies

Mitsubishi Chemical Corporation and

Taiyo Nippon Sanso Corporation

today announced plans to jointly market

a dehydration system using

the MCC-developed ZEBREXTM zeolite membranes

for bioethanol production processes in the U.S

MCC provides

the zeolite membranes and modules

and its group company,

Mitsubishi Chemical Engineering Corporation,

manufactures the dehydration system.

TNSC will support marketing and business development activities

via its wholly-owned U.S. subsidiary,

Matheson Tri-Gas, Inc. (MTG).

Bioethanol is made mostly from biomass

such as sugar cane and corn. It has been become widespread

as a fuel all over the world, particularly in

the U.S. and Brazil, in step with efforts to reduce CO2 emissions

and promote the carbon neutral movement.

The U.S. now has 215 bioethanol plants in operation,

with a combined annual capacity of 50 million kl,

backed by increasing demand as a gasoline additive

due to the enactment of the 1990 revised Clean Air Act

and 2005 Energy Policy, and

more plants are slated for construction.

The bioethanol production process includes

preliminary treatment such as

pulverization of the raw materials, conversion to sugar,

fermentation, refining (distillation), and

water removal.

The raw materials have high water content,

so the distillation process in particular requires

a large facility and considerable energy.

Producers in California and other West Coast states

face high energy costs, making energy-saving processes

a critical element.

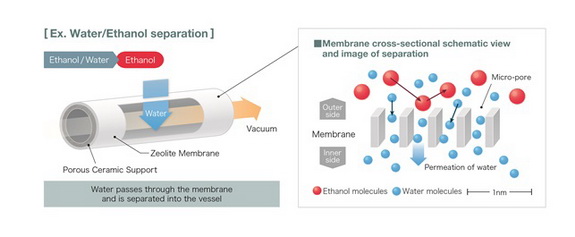

ZEBREXTM is a chabazite zeolite,

the world’s first to succeed in making zeolite into a membrane,

in which all pores are a uniform 3.8Å in size,

increasing separation capacity.

This allows higher production efficiency (Fig.1).

It also has higher water resistance compared to

conventional zeolite membranes, which allows

it to separate ethanol and isopropanol

from water in high-water-content environments

that deteriorate conventional zeolite membranes.

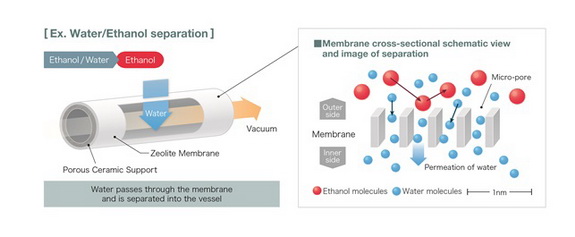

A dehydration system using ZEBREXTM membrane

in the bioethanol production process has the potential

to reduce energy consumption by 5% to 10%

and boost production by 10%

compared to

distillation and use of conventional zeolite membranes

now in use at many plants.

TNSC consolidated its U.S. subsidiaries

Matheson Gas Products, Inc. and Tri-Gas, Inc.

into MTG in 1999.

Through mergers and acquisitions, as well as

construction of air separation units, it established

a business network that covers the major industrial gas markets.

MCC and TNSC will draw upon that network

to develop the dehydration system

for bioethanol production processes.

WWW.CHEMWINFO.COM BY KHUN PHICHAI