20 July 2015

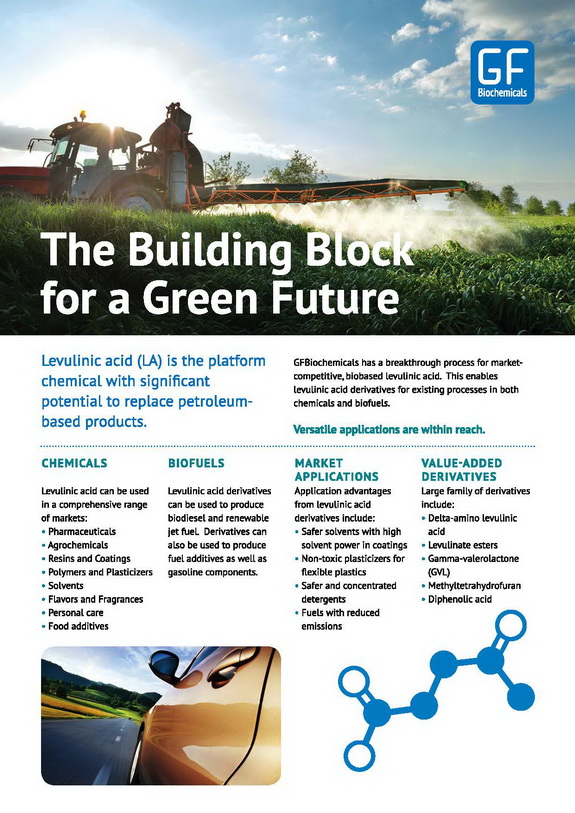

GFBiochemicals Founded in 2008, GFBiochemicals uses

breakthrough technology to commercialize

– a valuable biobased building block for

specialty chemicals and materials.

With offices in Milan, Italy and Geleen, the Netherlands,

its commercial-scale production plant is based in Caserta, Italy.

Personnel have decades of proven experience in

innovation, production and

business development of biobased chemicals.

ABOUT LEVULINIC ACID : USE AND APPLICATIONS

Pharmaceuticals

Levulinic Acid is used in

anti-inflammatory (e.g. indomethacin), anti-allergy agents,

mineral supplements (e.g. calcium levulinate) and

transdermal patches.

Levulinic Acid derivative

delta-amino Levulinic Acid (DALA) has increased consumption

in pharma in photodynamic treatment or diagnostics of cancer.

Flavors and fragrances

Levulinic Acid has a sweet, creamy, acidic, buttery,

guaiacol-like odour and commonly used in compositions

to create caramel, butterscotch, brown sugar, maple flavours.

Levulinic Acid esters are often used as niche fruity flavour

and fragrance ingredients.

Ethyl levulinate is a potential replacement for valencene,

a flavor currently extracted from oranges and

used in most beverages.

In Food applications Levulinic Acid

is used for multiple functions such as:

* flavoring agent derivative levulinate ester,

* alkaline earth metal salt to inhibit microbial growth in foods,

* pH regulator for food ingredients and disinfectant of fruit surfaces.

Personal care

Levulinic Acid and its derivatives are used in organic

and natural cosmetic compositions for antimicrobial, perfuming,

skin conditioning and pH-regulating purposes.

They give inherent fresh odor, prevent wrinkles,

stabilise formulations and emulsion.

Resins and coatings

Levulinic Acid can be used in

polyester coating resins, powder coatings,

unsaturated polyester resins and polyester polyols

to increase scratch resistance for interior and exterior coatings.

Diphenolic acid (DPA)

DPA is easily made from levulinic aicd.

It is a commercial chemical that will be far more attractive

at the lower cost allowed by Levulinic Acid production route.

DPA is used in some protective and decorative finishes,

but in recent years its use has been largely replaced by

the less expensive, toxic bisphenol‑A (BPA).

DPA has the potential to present itself in the future,

as a better, economical, eco-friendly and

renewable alternative to bisphenol‑A.

Polymers and plasticizers

Plasticizers are organic esters used to render polyvinyl chloride,

or PVC, more flexible. PVC is used in multiple end-markets

because it is low cost, durable and versatile.

Levulinic Acid ketal ester drivatives

can replace major phthalate-based plasticisers

which account for the majority of world’s plasticiser market.

Demand is increasing for renewable, phthalate-free plasticizers,

in applications for children’s toys and articles

as well as for products with human contact exposure.

Solvents

Gammavalerolactone (GVL)

GVL can be economically comparable with ethyl acetate,

but has value advantage with higher solvating power and

lower vapor pressure for applications in

paint stripping, softening polymers, or solubilizing intermediates

in industrial processes.

Economical GVL can be a monomer for polyester-polymer and

starting material for pyrrolidinone isomers.

Levulinic Acid based-isomers have reduced toxicity,

making them widely applicable.

Methyltetrahydrofuran (MTHF)

MTHF is currently produced from furfural

which is produced from corn cobs.

MTHF can substitute THF due to its environmental advantages and

its non-carcinogenity. Because of its lower water solubility

it is easier to recover from waste streams than THF and

generates fewer VOC emissions.

1,4-Pentanediol (PDO)

PDO can be obtained from Levulinic Acid similarly as GVL and MTHF,

but with different catalyst. A chemical similar to 1,4-Pentianediol

has existing demand for polyurethanes, but is relatively expensive.

PDO has environmental and safety advantages due to

its reduced potential leaching out other chemicals.

Alpha-methylene-gammavalerolactone (alfa-mGVL)

alfa-mGVL is a top-performing glass temperature booster

to increase functionality and performance of low-cost plastics.

It is considered for Plexiglass to improve its hardness

for scratch resistance for use to replace glass.

Its potential use is in consumer electronics, like touch-screens.

Derivatives

Levulinic Acid offers one of the largest families of

value-added derivatives. These include:

Gammavalerolactone (GVL)

Methyltetrahydrofuran (MeTHF)

1,4-Pentanediol (PDO)

Alpha-methylene-gammavalerolactone (alpha‑mGVL)

Delta-amino Levulinic Acid (DALA)

Levulinic Acid esters (LA-esters)

Diphenolic acid (DPA)

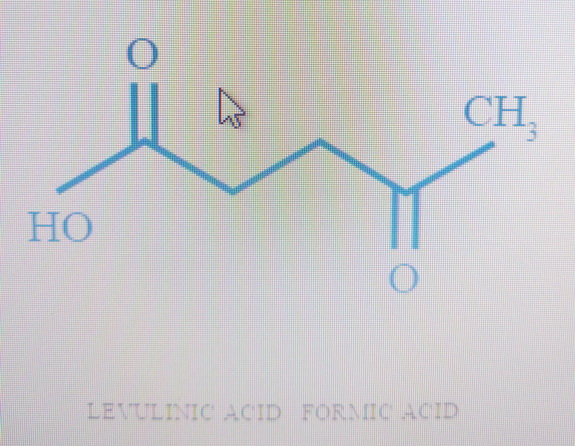

BY-PRODUCTS

Levulinic Acid production creates

useful value-added secondary chemicals.

Formic acid (FA)

Formic acid is a well-known industrial chemical

with an annual production capacity of around 800kt.

Its main used is as a preservative in life stock feed including silage.

The leather industry also consumes considerable amounts of formic acid

for tanning and finishing purposes. It is additionally used in

cleaning products where acidity is necessary in various applications.

Formic acid is a co-product of the Levulinic Acid production.

For every molecule Levulinic Acid produced in our process

one molecule of formic acid is formed as well.

DETAILS

Biobased chemical company GFBiochemicals

has started commercial production

at its 10,000 MT/a capacity levulinic acid plant

in Caserta, Italy.

The announcement was made at the BIO World Congress

on Industrial Biotechnology, Montreal.

GFBiochemicals is the first company to produce

levulinic acid at commercial scale directly from biomass.

Maxim Katinov

CEO

“GFBiochemicals has successfully achieved a substantial milestone

– the start-up of commercial-scale production.

I would like to praise and thank our engineering and R&D teams

who have clearly demonstrated the company’s ability

to deliver results on schedule.”

Marcel van Berkel

Chief Commercial Officer

“Caserta is now the world's largest operational production plant

for levulinic acid,”

“A fundamentally lower price range is now possible

using our unique technology.

This will give access to previously undiscovered market segments.”

Media Contact

Kathryn Sheridan

Sustainability Consult

ks@sustainabilityconsult.com

Europe: +32 496 116198

North America: (202) 470 3239

WWW.CHEMWINFO.COM BY KHUN PHICHAI