13 July 2015

READ LANZATECH EXECUTIVE SUMMARY

LanzaTech : Process scale-up and Commercialization

2008 : Blue Scope/ New Zealand

2012 : Baosteel/ China

2013 : Capital Steel/China

2015 : Freedom Pines/ USA

Lanzatech : waste carbon as a Resources for product synthesis

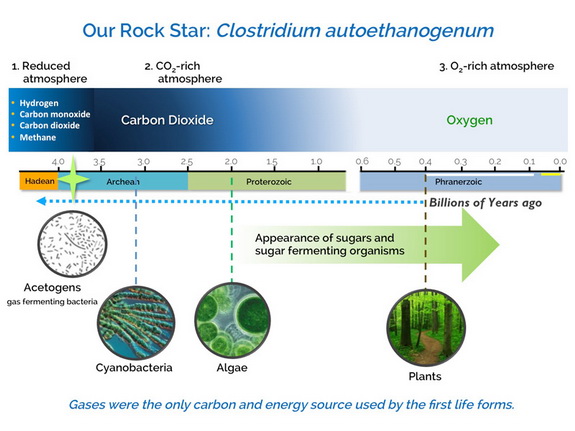

Lanzatech : Clostridium autoethanogenum

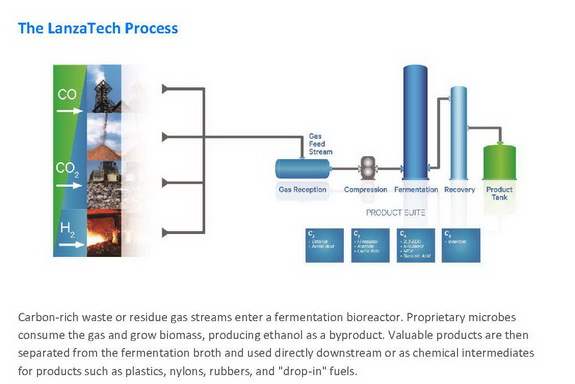

THE LANZATECH PROCESS

DETAILS

the world’s leading steel and mining company,

the carbon recycling company, and

Primetals Technologies,

a leading technology and service provider

to the iron and steel industry

today announce they have entered into

a letter of intent to construct

Europe’s first-ever commercial scale production facility

to create bioethanol from waste gases produced during

the steelmaking process.

The resulting bioethanol can cut greenhouse gas emissions

by over 80 per cent compared with conventional fossil fuels.

It will predominantly be used in gasoline blending,

but it can also be further processed into other products

such as drop in jet fuel.

The 47,000 ton ethanol/annum project,

sufficient to fuel half a million cars with ethanol blended gasoline,

will demonstrate the added value of recycling waste streams,

not only by reducing emissions at source,

hence reducing ArcelorMittal’s direct carbon footprint,

but by keeping fossil fuels in the ground

through the production of commodity chemicals and fuels

that would otherwise be made from oil.

Approximately 50 per cent of the carbon

used in the chemistry of steelmaking leaves the process

as carbon monoxide.

Today, this waste gas stream is either flared or used to heat and

power the steel mill. In either case, the carbon monoxide

is combusted and the resulting CO2 is emitted.

LanzaTech’s technology, however,

recycles the waste gases and ferments them with a proprietary microbe

to produce bioethanol.

Every ton of bioethanol produced, displaces 5.2 barrels of gasoline

as well as reducing ArcelorMittal’s CO2 emissions by 2.3 tons.

WWW.CHEMWINFO.COM BY KHUN PHICHAI