19 February 2015

Lummus Novolen Technology GmbH (Novolen),

a part of CB&I, licenses the

Novolen® gas-phase polypropylene process worldwide

on the basis of Ziegler-Natta and metallocene catalysts

for the production of a full range of polypropylene resins

Integration Synergy

CB&I’s on-purpose technologies

for the production of polymer grade propylene,

such as

1.CATOFIN® dehydrogenation and

2.Olefins Conversions Technology (OCT)

allows licensors all over the world to benefit from

the synergies provided when combining those

in-house technologies with

Novolen’s polypropylene technology.

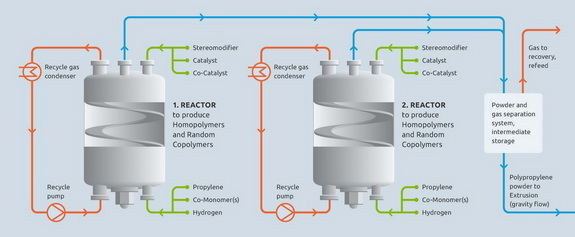

Simplified Novolen Process Schemes

The Novolen process utilizes

one or two identical vertical gas-phase stirred bed reactors.

Homopolymers and random copolymers

can be manufactured either

in a single reactor or in a reactor cascade with two reactors,

depending on the required capacity and product range.

Alternatively, two reactors can be operated

in parallel to achieve higher capacities

for a single train plant and to produce bimodal resins.

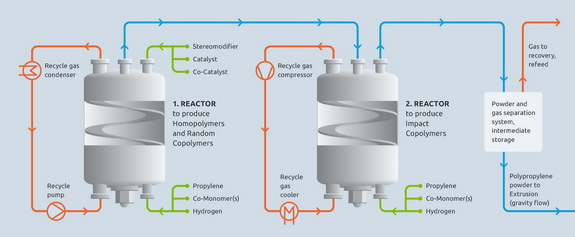

A cascade reactor configuration

is required for the production of impact copolymers,

whereas in the first reactor

a propylene homopolymer (or random copolymer) matrix

is polymerized and

in the second reactor the ethylene-propylene rubber (EPR)

is produced.

Independent from the configuration chosen,

all reactors are identical in design, size and material.

Parallel Configuration (Homo, Random)

Cascade Configuration (Homo, Random, Impact)

DETAILS

CB&I (NYSE:CBI)

today announced it has been awarded a contract by

Carbon Holdings

for the license and engineering design of a polypropylene unit

to be built in Ain Sokhna, Egypt.

The unit will be aligned to the Tahrir petrochemical complex

and use CB&I's Novolen® technology

to produce 350,000 metric tons per annum of polypropylene.

WWW.CHEMWINFO.COM BY KHUN PHICHAI