7 November 2014

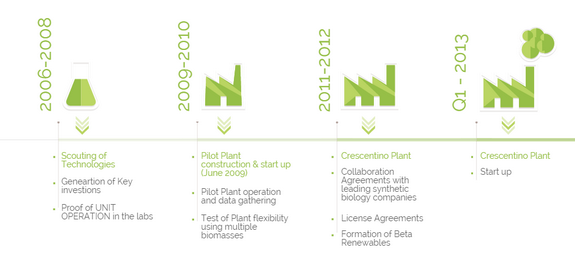

is the world leading process for

converting cellulosic feeds non-competing

with food industry, into petroleum products.

The second generation bioethanol product

will help meet future regulatory specifications.

This technology is becoming increasingly important.

Additionally, it offers a new way of processing

non-food biomasses that were unusable

in fermentation processes.

- Proesa™ is cost-competitive even

with oil at 70 USD per barrel,

a price which today is basically unattainable. - One metric ton of fuel grade ethanol

needs about 4.5 to 5.0 metric tons of dry biomass - Reduced capital investment required

(simple process, non-sophisticated plant design) - Positive economic performance even

at modest scale. - Cash cost of fermentable sugars: 0.2 €/kg.

- Cash cost of ethanol: 0.3 €/liter.

- Energy content of lignin co-product

entirely self-sustains plant operation. - Competitive on a global scale,

without need for subsidies. - Maximum flexibility in use of feedstock:

dedicated varieties such as

Arundo donax (energy crops), agricultural residues,

woody biomass, bagasse, etc.

DETAILS

Technip in Italy and Biochemtex,

who is the majority shareholder of

Beta Renewables

who controls the world’s leading

second generation bioethanol technology (PROESA),

announce today that they have signed

an alliance agreement for future

Biochemtex Second Generation Bioethanol projects.

This alliance aims to achieve industry leading capital productivity,

through the highest standards of

* Health, Safety and Environment (HSE),

* operability, accelerated technological innovation,

* project execution related developments and

* reduced project cycle times.

Technip’s operating center in Rome, Italy,

will be in charge of the alliance’s management,

as it is a reference and

one of the main execution centers at Technip for biofuels.

WWW.CHEMWINFO.COM BY KHUN PHICHAI