7 July 2014

Details

The formation of

Maverick Northstar, Inc.,

a joint venture to facilitate

the deployment and operation of

gas-to-liquids (GTL) technology

in the Canadian Provinces of Alberta,

British Columbia and Saskatchewan.

The small-scale modular plants

will utilize and promote technology that

converts

a methane-rich feedstock,

such as natural gas, flare gas and biogas,

into high-quality methanol,

which offers new possibilities

for synthetic chemicals and fuel production

in Canada’s methane-rich prairie provinces.

Products

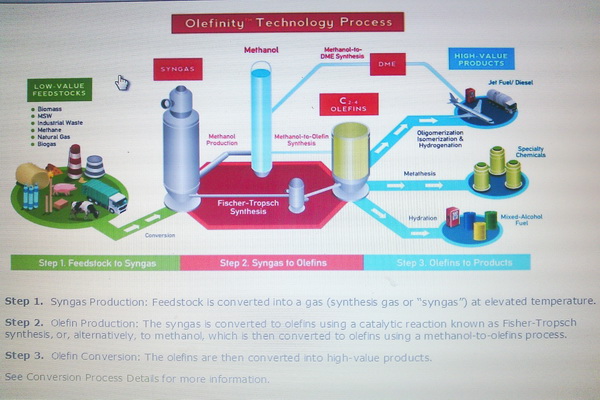

Maverick Synfuels uses

proven, clean-energy technology

to convert low-value feedstocks such as

* natural gas,

* purpose-grown biomass,

* waste biomass, and landfill/industrial waste

into high-value chemicals and fuels

at a relatively low overall cost.

Maverick’s primary products are

* diesel/jet fuel,

* propylene (polypropylene) and

* mixed alcohols.

Secondary products include

* methanol,

* bio-LPG, and

* heat or steam at larger refineries.

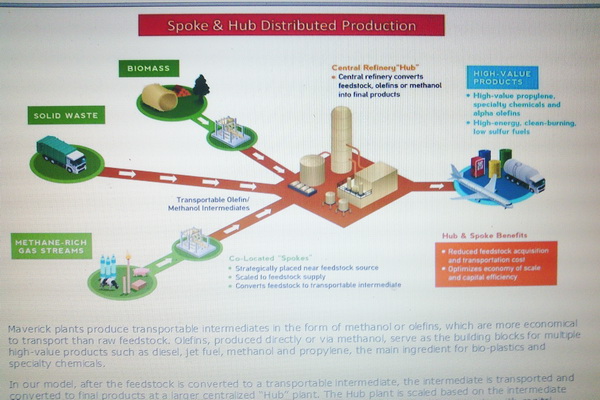

Maverick’s spoke-and-hub distributed plants

produce transportable intermediates

in the form of methanol or olefins,

which are more economical to transport

than raw feedstock.

Olefins, produced directly or via methanol,

serve as the building blocks

for multiple high-value products

such as diesel, jet fuel, methanol and propylene,

the main ingredient for bio-plastics and

specialty chemicals.

The choice of which route to take depends on

a number of factors, including

the feedstock, the location, the size of the plant, and

the product needs of the local market.

Maverick_Synfuels_Value_Proposition

Methanol:

Methane-rich feedstocks are well suited

for the production of methanol.

There is a large commercial market for methanol,

so the methanol may initially be sold to this market

while Maverick is planning or constructing central hubs.

Diesel/Jet Fuel:

Maverick’s diesel and jet fuels are

clean burning low sulfur fuels that,

when blended, meets all required ASTM standards.

Propylene:

Whether we initially produce a mixture of olefins,

or convert methanol to a mixture of olefins,

we have patent-pending processes

to convert the mixture to

pure propylene.

Because this propylene can be derived

from bio-based feedstocks,

the resulting polypropylene is

a bio-based polymer

with the same properties as

crude oil-derived polypropylene.

Mixed-Alcohol:

With 80-85% of the energy of gasoline,

Maverick’s mixed-alcohol biofuel is

a superior replacement for ethanol in gasoline blends,

and can eliminate the use of gasoline

in flexible-fuel vehicles.

Maverick’s mixed-alcohol biofuels are

cleaner-burning than gasoline, and

are distribution-channel friendly.

Unlike first generation ethanol-based biofuels

that rely on edible feedstocks,

Maverick’s gasification-based process can

convert biomass in the form of

wastes (crop, timber, landfill, etc.) or

purpose-grown feedstocks

(such as Switchgrass, Miscanthus, and other grasses)

into biofuels, and

conventional feedstocks,

such as natural gas, into alternative fuels.

Bio-LPG:

Some of our processes also produce

a by-product that has the energy density of

liquefied petroleum gas (LPG).

Because the boiling point of this product is significantly

lower than that of our other products,

this by-product can be easily obtained and

shipped to a variety of end-users.

For example, the LPG-like product can be used

to heat homes, as a cooking fuel, and

as a transportation fuel.

WWW.CHEMWINFO.COM BY KHUN PHICHAI