5 March 2014

Details

Process performance validated for key components;

now scaling up

Monmouth Junction, NJ – March 5, 2014

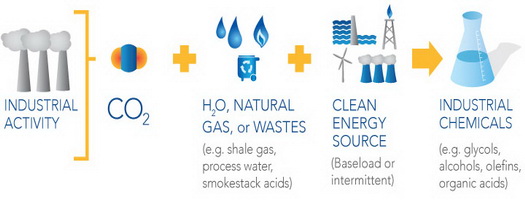

unveiled its new process

for the production of major chemicals

from carbon dioxide (CO2),

showcasing its demonstration-scale

‘reaction cell’ and confirming the potential

for cost-advantaged process economics.

Because carbon dioxide — a greenhouse gas —

is low-cost and readily available worldwide,

Liquid Light’s customers can profit by

producing high-value chemicals from CO2‘waste’;

reduce their dependence on oil;

and potentially reduce their carbon footprint.

Liquid Light’s first process is

for the production of ethylene glycol (MEG),

with a $27 billion annual market,

which is used to make a wide range of

consumer products such as

plastic bottles, antifreeze and polyester clothing.

Liquid Light’s technology can be used to

produce more than 60 chemicals

with large existing markets, including

* propylene,

* isopropanol,

* methyl-methacrylate and

* acetic acid.

WWW.CHEMWINFO.COM BY KHUN PHICHAI