25 March 2014

Details

HONG KONG

the largest distributor of specialty chemicals and

ingredients in Asia-Pacific,

announced today that it has partnered with

a leading specialty materials company,

to market Lehigh’s PolyDyne™

to the tire and rubber industries

in Japan and Korea.

After initial success in Japan,

the two companies will focus on

* broadening industry outreach,

* supply chain efficiency and

* technical support in Japan,

as well as introducing MRP to

Korea and Southeast Asia.

said Azita Owlia,

vice president for north Asia at CBC.

Following two years of market development,

MRP—produced from

end-of-life tires and post-industrial rubber—

has helped meet growing demand for

affordable, high performance and

sustainable raw materials in Japan,

one of the world’s leading automotive markets.

“The Japanese tire and rubber industries

have always shown clear demand for

specialty materials that offer

cost and environmental benefits,”

“These materials also need to

meet stringent performance criteria,

given Japan’s best-in-class quality and

safety standards for tire manufacturing.

Lehigh’s PolyDyne MRP

delivers all of these benefits,

and we expect that the partnership

will expand the MRP customer base in Japan.

Encouraged by our success in Japan,

we also expect to develop a market for

PolyDyne™ in Korea,

another leading automotive manufacturing hub in Asia.”

In recent years,

many tire and rubber companies

have implemented robust sustainability and

waste reduction programs

to address the end-of-life tires produced by

the automotive industry each year.

By transforming these end-of-life tires

into new materials,

MRP can help the automotive sector

meet environmental goals

without paying a premium for sustainability.

Additionally, incorporating MRP into new tires

provides crucial environmental benefits via

energy savings and

reducing virgin rubber consumption.

Connell Brothers currently provides

marketing, sales, supply chain and

technical support for

Lehigh’s PolyDyne™ product in Japan.

The company is deploying its technical knowledge

and understanding of the products, applications,

local regulations and culture of Japan

to bridge the requirements of

local downstream tire manufacturers and

the products available from leading global suppliers.

said Alan Barton,

CEO of Lehigh Technologies.

“With one of the largest automotive sectors in the world,

Asia is an important market for MRP,”

“Our MRP has already been used

to make more than 250 million tires globally,

and our customer base includes

six of the top 10 tire companies in the world.

Thanks to Connell Brothers’ commercial strengths

and excellent technical sales team,

we have successfully introduced MRP

to the Japanese market.

We are now working to boost our capabilities

in the region in order to leverage

this traction and accelerate MRP adoption,

as well as to introduce MRP to other markets

in the Asia-Pacific region.”

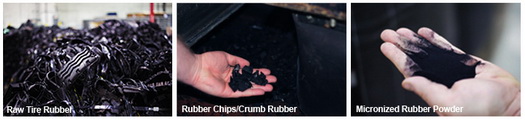

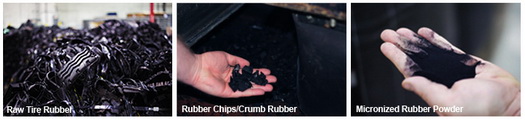

What is Micronized Rubber Powder

Lehigh Technologies’ micronized rubber powder (MRP)

–transformed from end-of-life tires and

other post-industrial rubber–

is a lower cost, high-performance,

sustainable specialty material that

replaces oil- and rubber-based materials

to reduce costs and cut waste.

These micron-scale powders

are sold to manufacturers of advanced products,

including

* high-performance tires,

* industrial rubber,

* consumer and industrial plastics goods,

* asphalt and

* coatings and

* construction materials.

WWW.CHEMWINFO.COM BY KHUN PHICHAI