16 October 2013

Details

Velocys plc.,

the technology innovator for

smaller scale gas-to-liquids (GTL),

is pleased to announce that

it has executed a commercial agreement with

PTT Public Company Limited (PTT)

to proceed with the commercial deployment of

the company's gas-to-liquids, GTL technology in

Thailand and other regions.

Milestones

- The two companies have been collaborating since

late 2009,

- In February 2010, under the term of an MOU,

PTT agreed to provide funding for the development and

commercialisation of the Company's

microchannel steam methane forming (SMR) technology.

- In 2012,

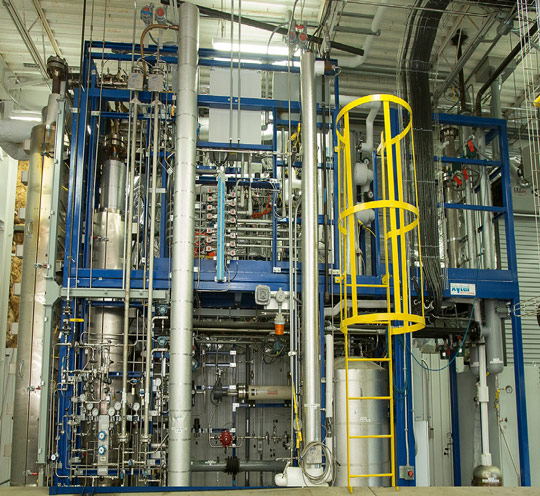

under the terms of a research collaboration with Velocys,

PTT opened a new experimental facility

for testing microchannel reactors at its

Research Institute in Wangnoi, Ayutthaya, Thailand.

- In the next phase of collaboration, PTT has commissioned

Toyo Engineering Corporation to prepare a detailed

front end engineering design (FEED) for a

100 barrel per day (bpd) GTL plant

that will incorporate the company

SMR and Fischer-Tropsch (FT) technologies.

The plant will be located at one of PTT's production facilities

in Thailand. The engineering study will be completed

in mid-2014 and will be followed by

the final investment decision and facility construction.

Velocys,

Roy-Lipski, CEO

- We're delighted to be working with PTT and

to be progressing with the design of

the integrated GTL plant using Velocys technologies.

- It stands to be the largest capacity modular GTL plant of its

kind commissioned anywhere in the world todate.

PTT,

Khun Pailin Chuchottaworn, President and CEO

- Synthetic fuels are a strategic growth areas for PTT,

We are pleased to progress our partnership with Velocys,

the leaders in smaller scale GTL.

About Velocys

- The company, Previously known as

" Oxford Catalyst Group Plc",

changed its name to

"Velocys Plc" in September 2013.

- Velocys plc is listed on AIM market of

the London Stock Exchange (LSE).

- GTL converts low value gas into high value clean fuels

such as Diesel and Jet fuels and

provides a significant financial opportunity.

- Smaller scale GTL, enabled by Velocys technology,

provides a cost-effective way to take advantage of

smaller scale and remote gas resources.

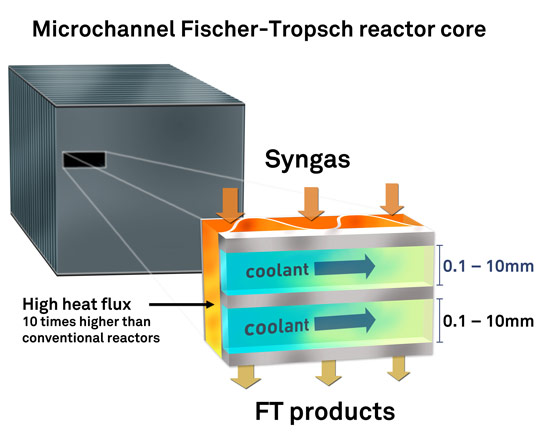

- The success of Velocys's smaller scale GTL technology

lies in the combination of microchannel reactors and

super-active catalysts that

together, significantly intensify the FT process.

- Smaller scale GTL also provides an alternative to

the flaring of associated gas, thereby unlocking

oil production in fields that would otherwise be

constrained by the regulation or taxation of flaring.

- Due to the modular construction methods, plants based on

the use of microchannel reactors are very flexible, and

can be easily scaled to match the size of the resources.

- The modular are of a standardized designed and

are shop-fabricated in skid-mounted units,

making them easier to transport to remote locations or

to integrate with existing facilities on

refinery or gas-processing sites.

- The construction approach reduces the costs and risks

associated with building plants in remote locations.

- Velocys enables gas-to-liquids (GTL) plant to convert

unconventional, remote and problem gas into

valuable liquid fuels.

WWW.CHEMWINFO.COM BY KHUN PHICHAI